Thin films are essential for creating layers of materials that are only a few nanometers to micrometers thick. The Georgia Tech Institute for Matter and Systems cleanroom offers extensive thin film capabilities, including e-beam and filament evaporators for precise deposition of metals and dielectrics, Plasma-Enhanced Chemical Vapor Deposition (PECVD) for silicon dioxide, silicon nitride, and amorphous silicon, Atomic Layer Deposition (ALD) for ultra-thin, conformal coatings of materials like aluminum oxide and hafnium oxide, and sputtering systems (both RF and DC) for a variety of materials including metals and oxides.

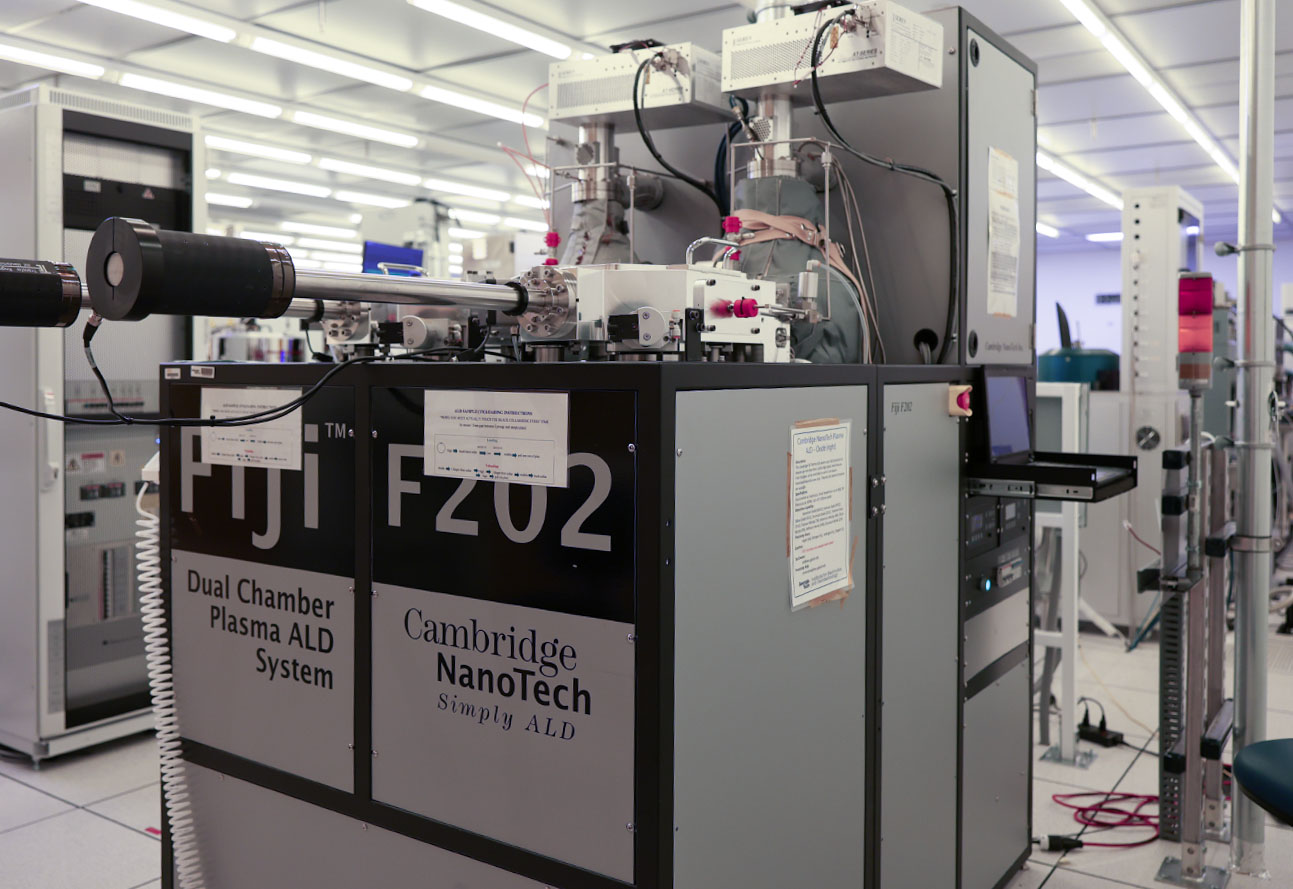

Cambridge Fiji Plasma Atomic Layer Deposition (ALD)

The Georgia Tech Cambridge Fiji Plasma Atomic Layer Deposition (ALD) system, Model: Fiji F202, uses ALD precursors to deposit atomic resolution, pin-hole free films in ultra-high aspect ratio features. Sample size can be from piece up to 8" (200mm) wafer. It can run both thermal and plasma ALD. Process temperature can be from room to 500C, with remote plasma up to 300W. Film thickness can be controlled to within 1nm. The dual chambers with load-locks have the following capabilities: Al2O3, AlN , HfO2, HfN, SiO2, TiO2, TiN, ZrO2, ZrN, ZnO, Pt.

Cambridge NanoTech Plasma ALD - Left | (IMS) IMS- Micro/Nano Fabricat

Cambridge NanoTech Plasma ALD - Right | (IMS) IMS- Micro/Nano Fabrica

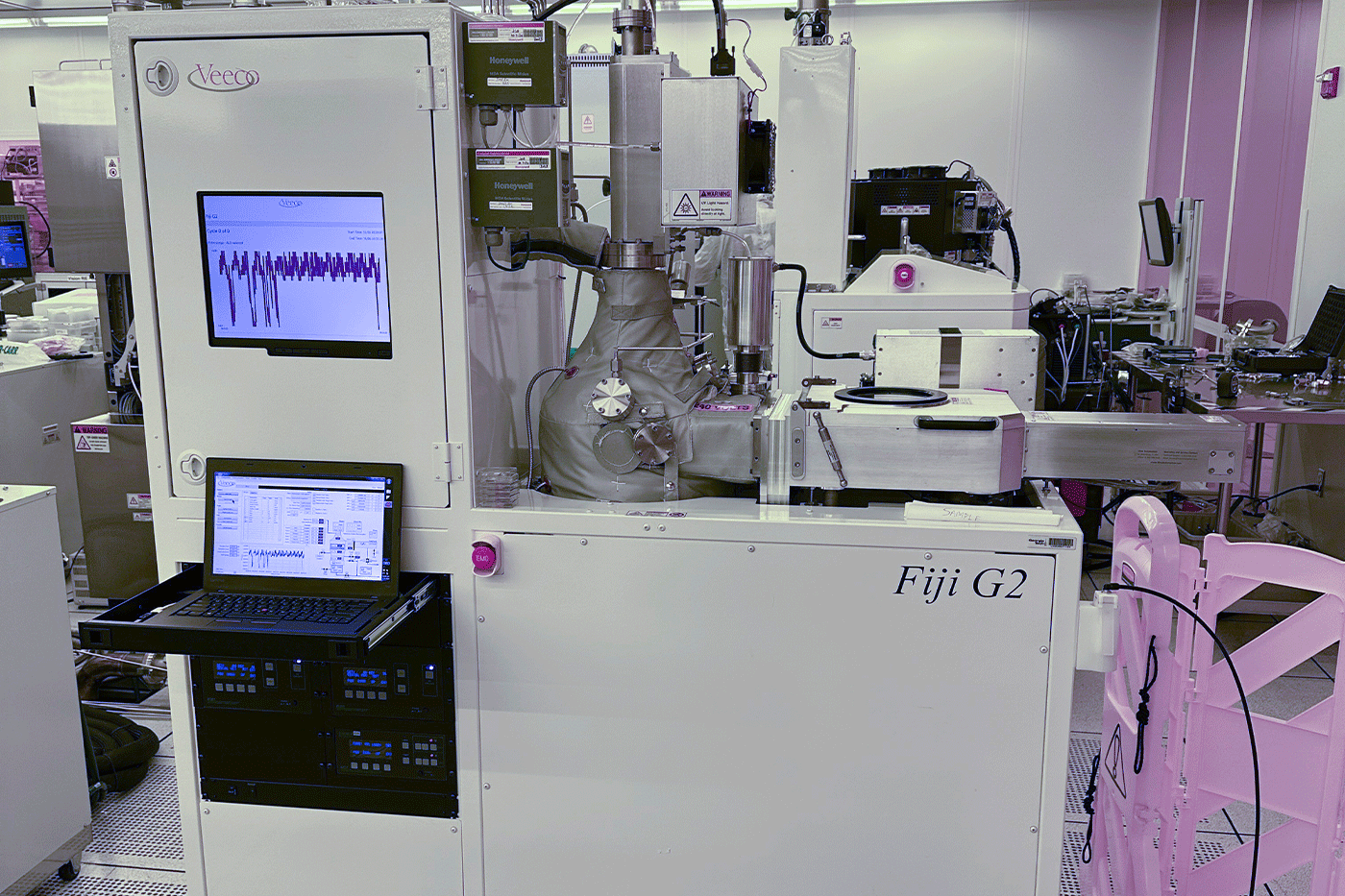

Veeco Fiji G2 Atomic Layer Deposition (ALD) No1

The Plasma Enhanced Atomic Layer Deposition System, a Veeco Fiji G2, is a modular, high-vacuum system accommodating multiple deposition modes using flexible system architecture and multiple configurations of precursors and plasma gases. The standard configuration of the Fiji G2 enables deposition of a wide range of materials including oxides, nitrides, and metals. Features of the Fiji G2 include:

- Plasma Enhanced ALD with an integrated Inductively Coupled Plasma (ICP) source

- Conventional Thermal ALD

- Exposure Mode Thermal ALD for high aspect ratio substrates

- Temperature controlled substrate holder, 200mm up to 500°C standard

- Reactor walls heated up to 300°C

- Individually controlled plasma gas source MFCs

- Main reactor turbo pump standard, with turbo pump

- Exposure modes include dynamic, static and Ozone source.

It has the following process capabilities: Al2O3, HfO2, TiO2, ZrO2, SiO2, AlN, HfN, TiN

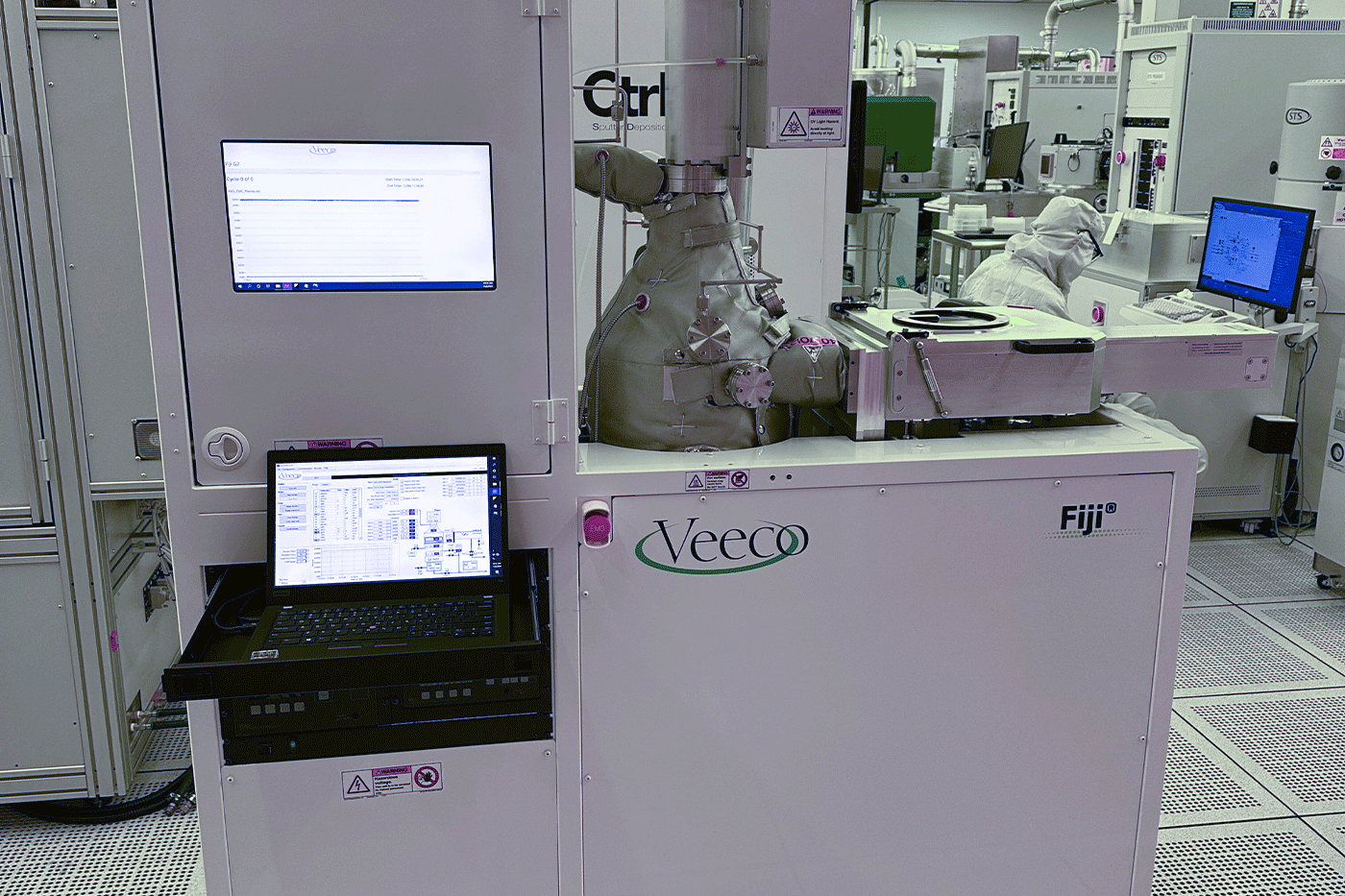

Veeco Fiji G2 Atomic Layer Deposition (ALD) No2

The Plasma Enhanced Atomic Layer Deposition System, a Veeco Fiji G2, is a modular, high-vacuum system accommodating multiple deposition modes using flexible system architecture and multiple configurations of precursors and plasma gases. The standard configuration of the Fiji G2 enables deposition of a wide range of materials including oxides, nitrides, and metals. Features of the Fiji G2 include:

- Plasma Enhanced ALD with an integrated Inductively Coupled Plasma (ICP) source

- Conventional Thermal ALD

- Exposure Mode Thermal ALD for high aspect ratio substrates

- Temperature controlled substrate holder, 200mm up to 500°C standard

- Reactor walls heated up to 300°C

- Individually controlled plasma gas source MFCs

- Main reactor turbo pump standard, with turbo pump

It has the following process capabilities: Al2O3, ln2O3, Ga2O3, SiO2, WO3

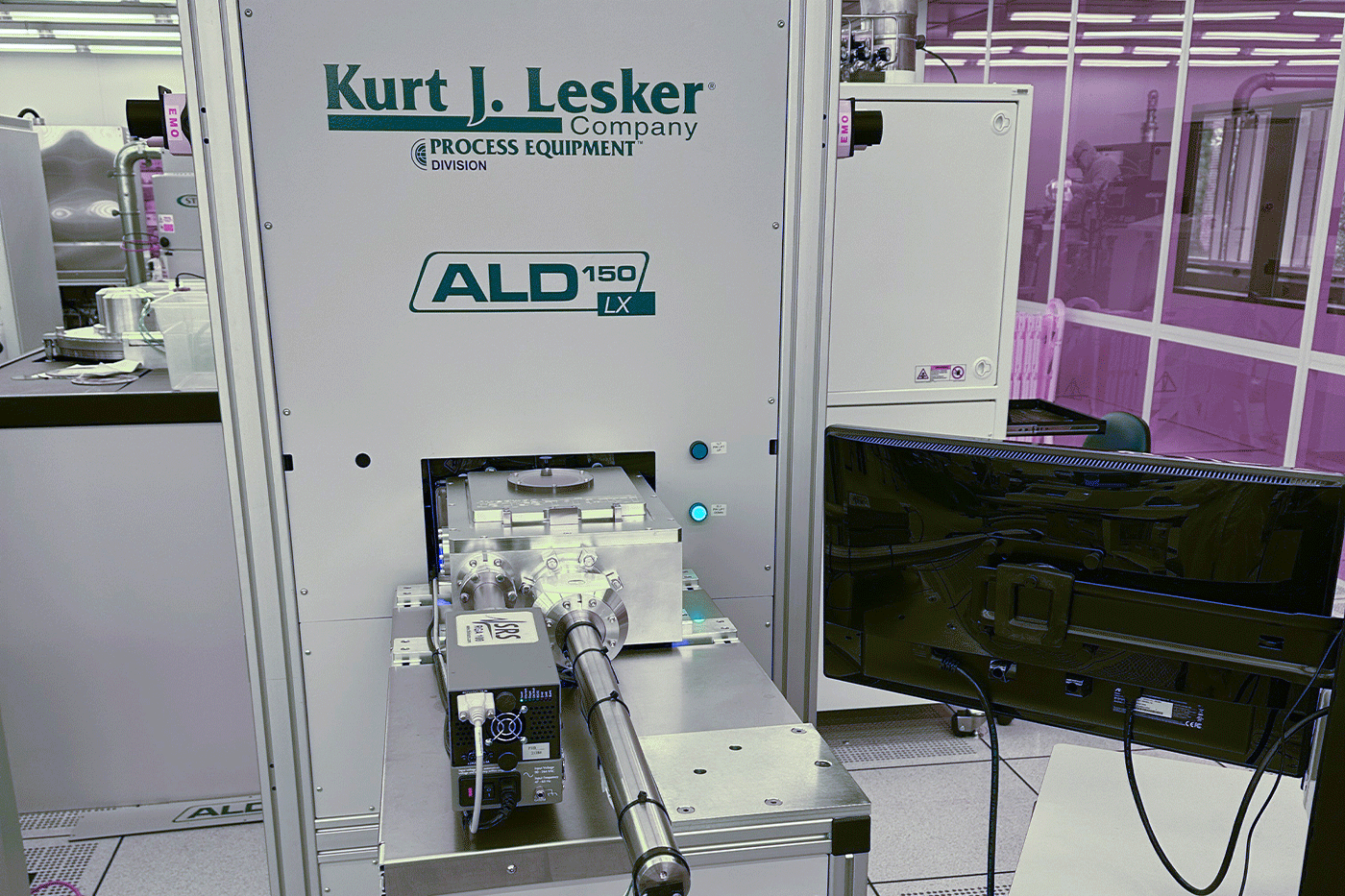

Lesker ALD150LX Atomic Layer Deposition (ALD)

The Kurt J. Lesker ALD150LX Atomic Layer Deposition (ALD) features UHV-type sealing enabling UHP process conditions and perpendicular flow design, as well as separate chamber inlets for precursor delivery. Additionally, it equips with analytical ports for in-situ ellipsometry or other techniques. High-performance, remote inductively coupled plasma (ICP) source connects with up to eight plasma gas lines, with a maximum of 1,000 W of ICP power. Exposure modes include dynamic, static and Ozone source. Independent substrate heater stage capable of up to 600°C operation. Process chamber and precursor delivery line heating up to 250°C It has the following process capabilities: Al2O3 , HfO2, ZrO2, TiO2

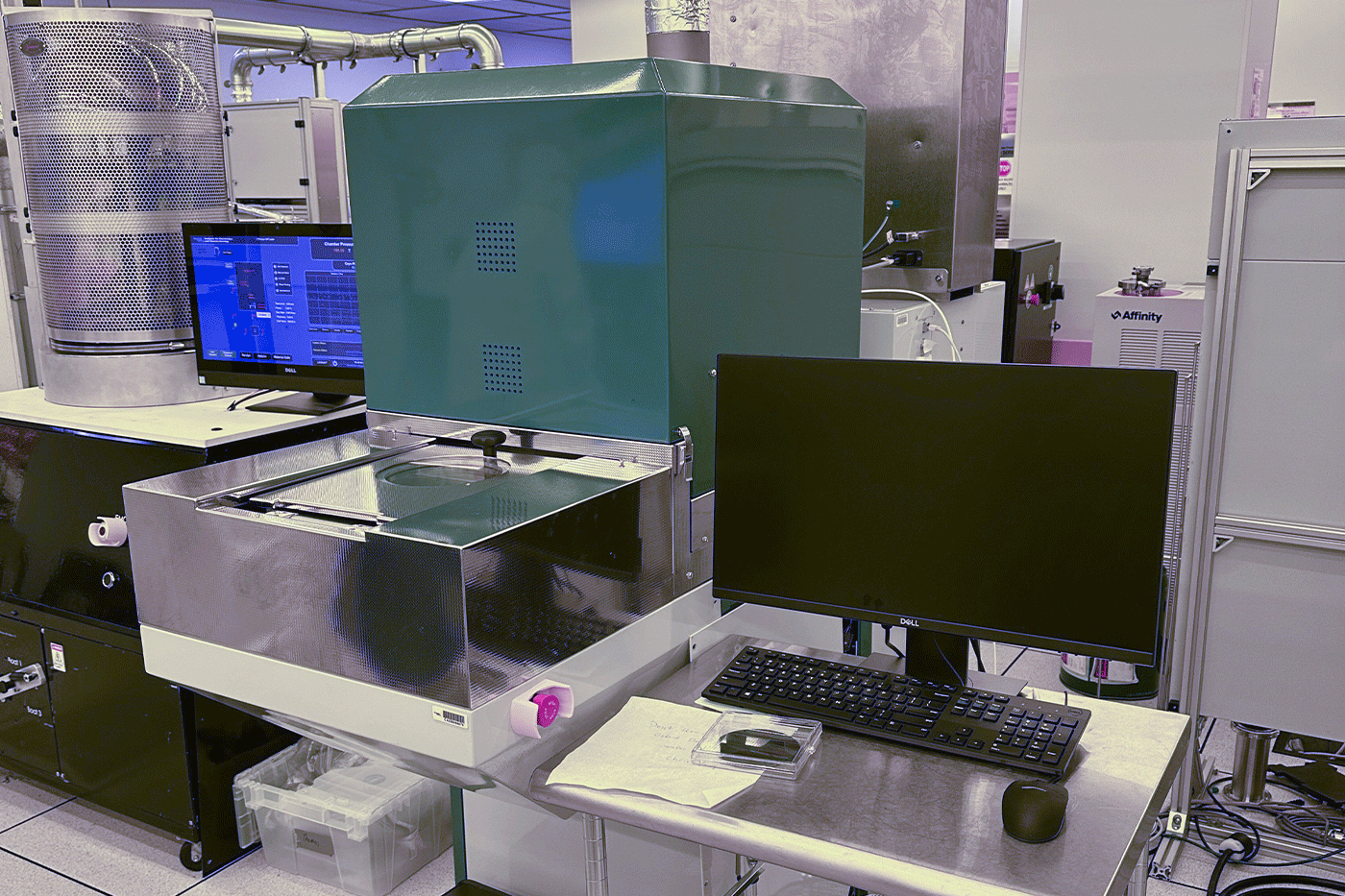

Oxford FlexAL ALD system

The Oxford FlexAL ALD is a single wafer processing system that can be run at low process pressure in a short pulse and quick purge. The process chamber can be configured to run a plasma process or a thermal ALD process. The plasma process uses radio frequency power to create plasma inside a plasma source. The reactive ionic species generated within the plasma are guided on to the front surface of the substrate. The thermal process uses elevated temperatures to promote deposition on the front surface of the substrate. Wafer sizes can be 4” or 8”, temperature ranges from room up to 350C. Currently, it has the following process capabilities: Al2O3 , HfO2.