Georgia Tech's cleanroom facilities offer advanced high-temperature solutions for micro/nano fabrication. These capabilities include high-temperature furnaces, vacuum ovens, and rapid thermal processing (RTP) systems. The high-temperature furnaces can handle a range of processes, including dry oxidation at temperatures between 700°C and 1150°C, with excellent uniformity. The vacuum ovens and RTP systems support rapid temperature changes and precise control, essential for various fabrication needs. These tools enable researchers to manipulate sample temperatures effectively, facilitating cutting-edge research and development in materials science and engineering.

Vacuum Ovens

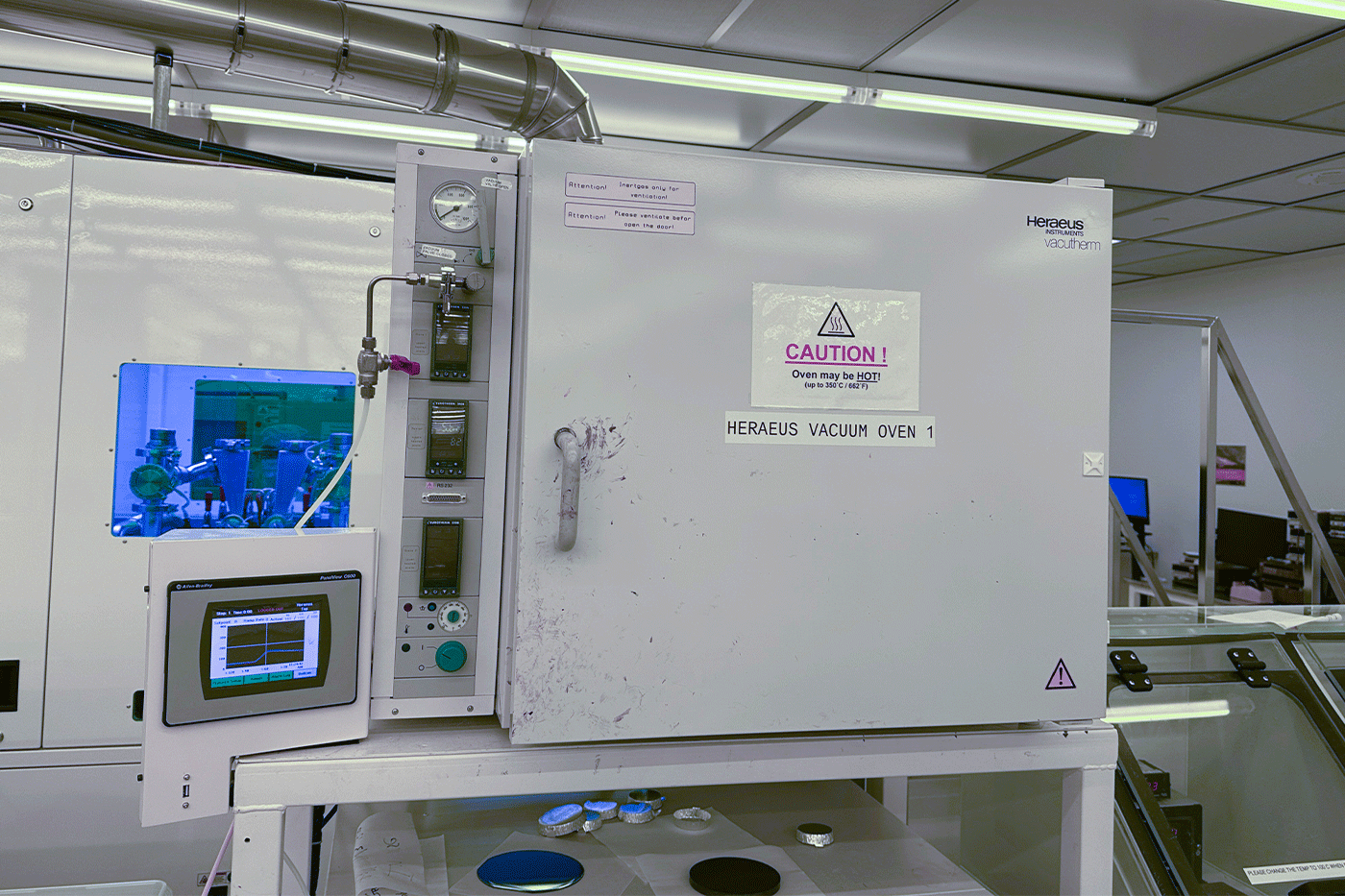

Heraeus Vacuum Oven 1

The Georgia Tech Heraeus Vacuum Oven used for heating of substrates under 5-10 milliTorr Vacuum and up to 350℃ under vacuum. The oven can be programmed to ramp, dwell, and cool down according to the user's specifications. The vacuum pressure for this oven (top oven) under nitrogen atmosphere can be controlled using a throttle-valve and nitrogen MFC.

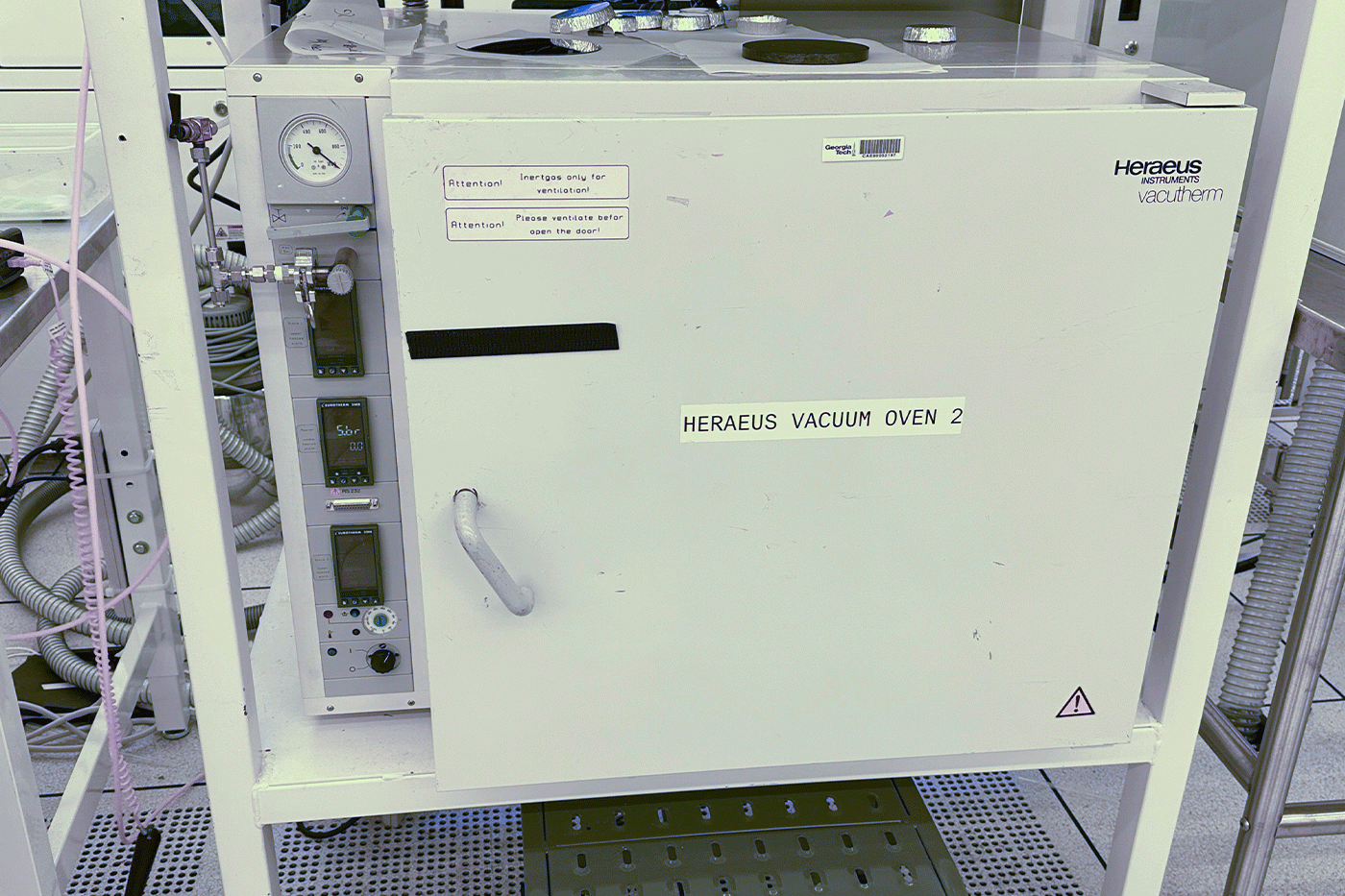

Heraeus Vacuum Oven 2

The Georgia Tech Heraeus Vacuum Oven used for heating of substrates under 5-10 milliTorr Vacuum and up to 350℃ under vacuum. The oven can be programmed to ramp, dwell, and cool down according to the user's specifications. The vacuum pressure for this oven (top oven) under nitrogen atmosphere can be controlled using a throttle-valve and nitrogen MFC.

Furnaces

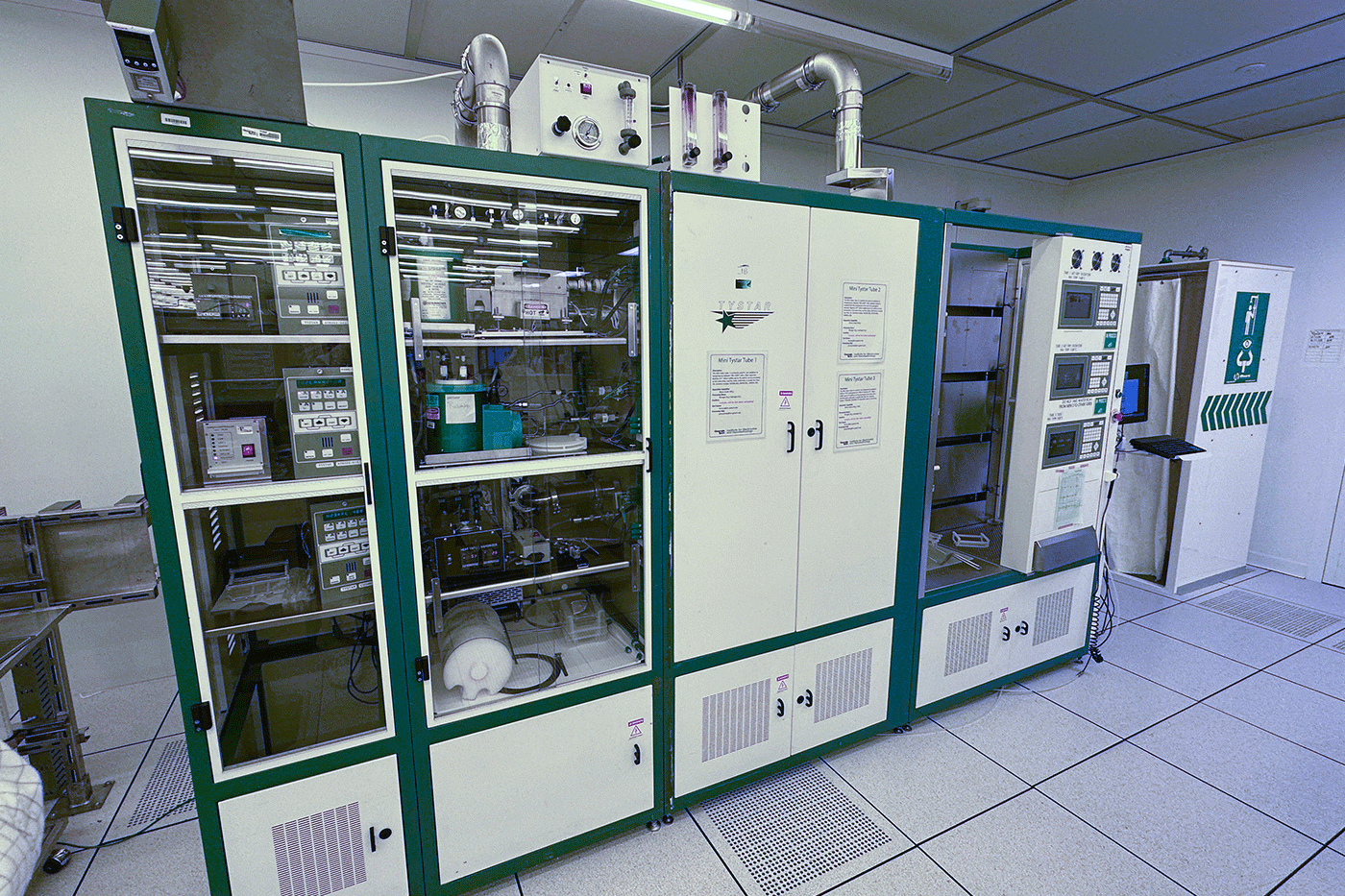

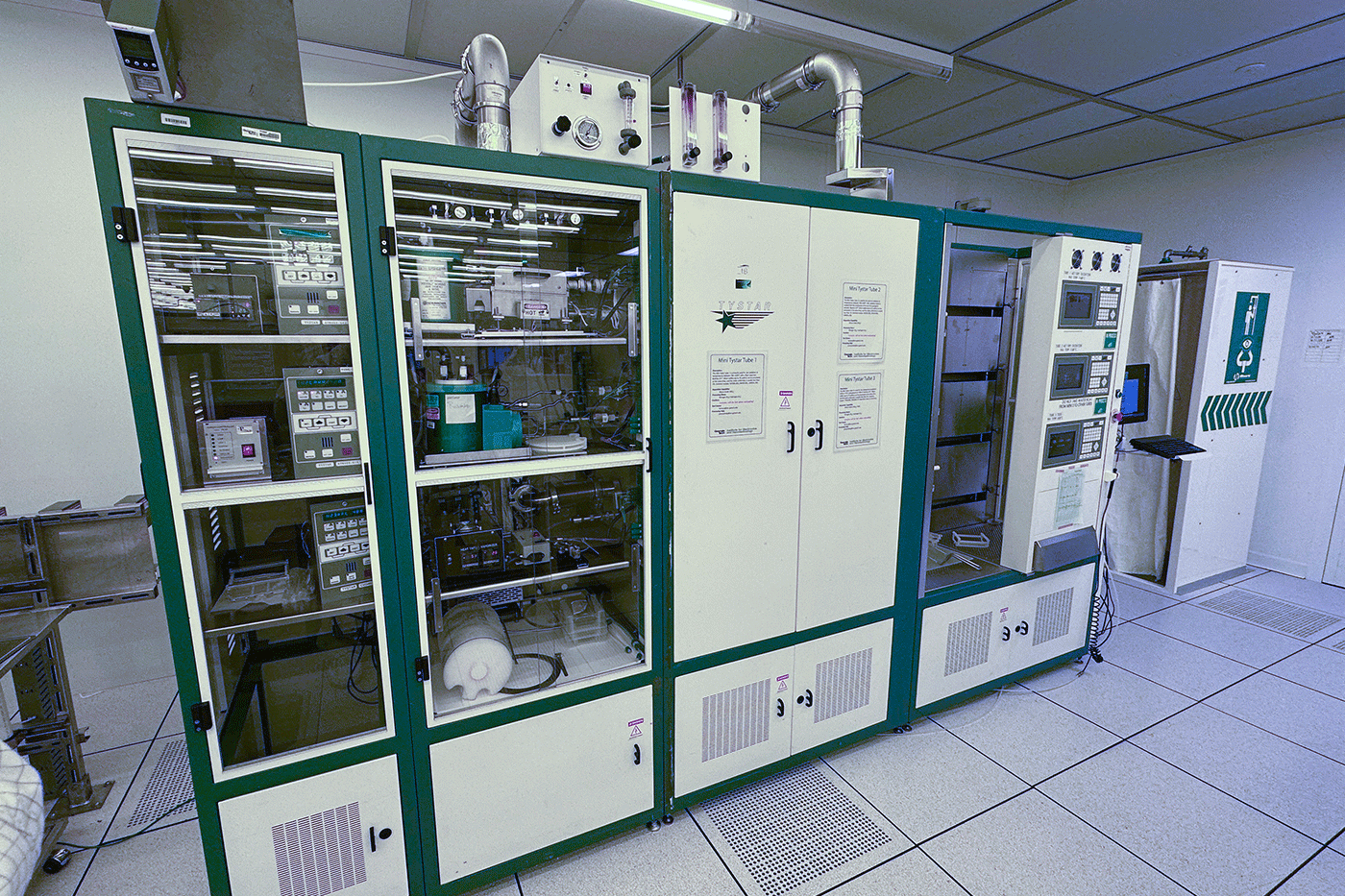

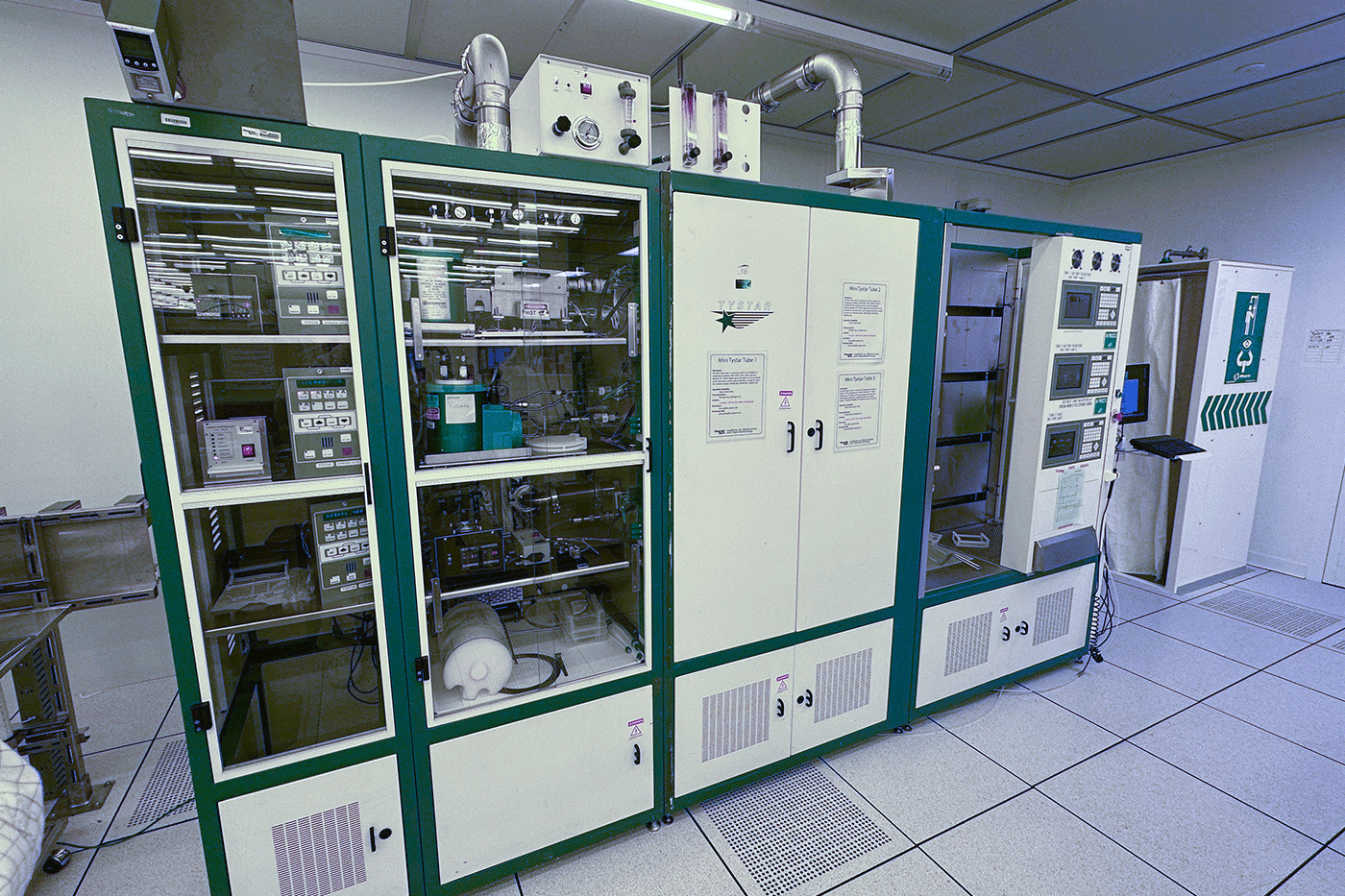

Tystar Mini Tube 1 (Mini Tystar 4600)

The Georgia Tech Mini Tystar 1 is primarily used for dry and wet oxidation at temperatures between 700-1100°C with a flash vaporizer. Batches of 4” silicon wafers (up to 25 wafers) can be processed at the same time, and the oxide uniformity is typically less than 1%. Common recipes including WETOX.001, DRYOX.001 and ANNEAL.001.

Tystar Mini Tube 2 (Mini Tystar 4600)

The Georgia Tech Mini Tystar 2 is used for dry and wet oxidation at temperatures between 700-1100°C. Wet oxidation steam is created from the combustion of H2 and O2 (a pyrogenic process). Batches of 4” silicon wafers (up to 25 wafers) can be processed at the same time, and the oxide uniformity is typically less than 1%. Common recipes including WETOX.002, DRYOX.002 and ANNEAL.002

Tystar Mini 3 TEOS Tube

The Georgia Tech Mini Tystar 3 is used for low temperature oxidation (LTO) up to 850 C and pressure of 300mT. The deposition rate of LTO is approximately 12 nm/min. Batches of 4” silicon wafers (up to 25 wafers) can be processed at the same time, and the oxide uniformity is usually less than 3%. Common recipes include TEOS.003 and STBY.003.

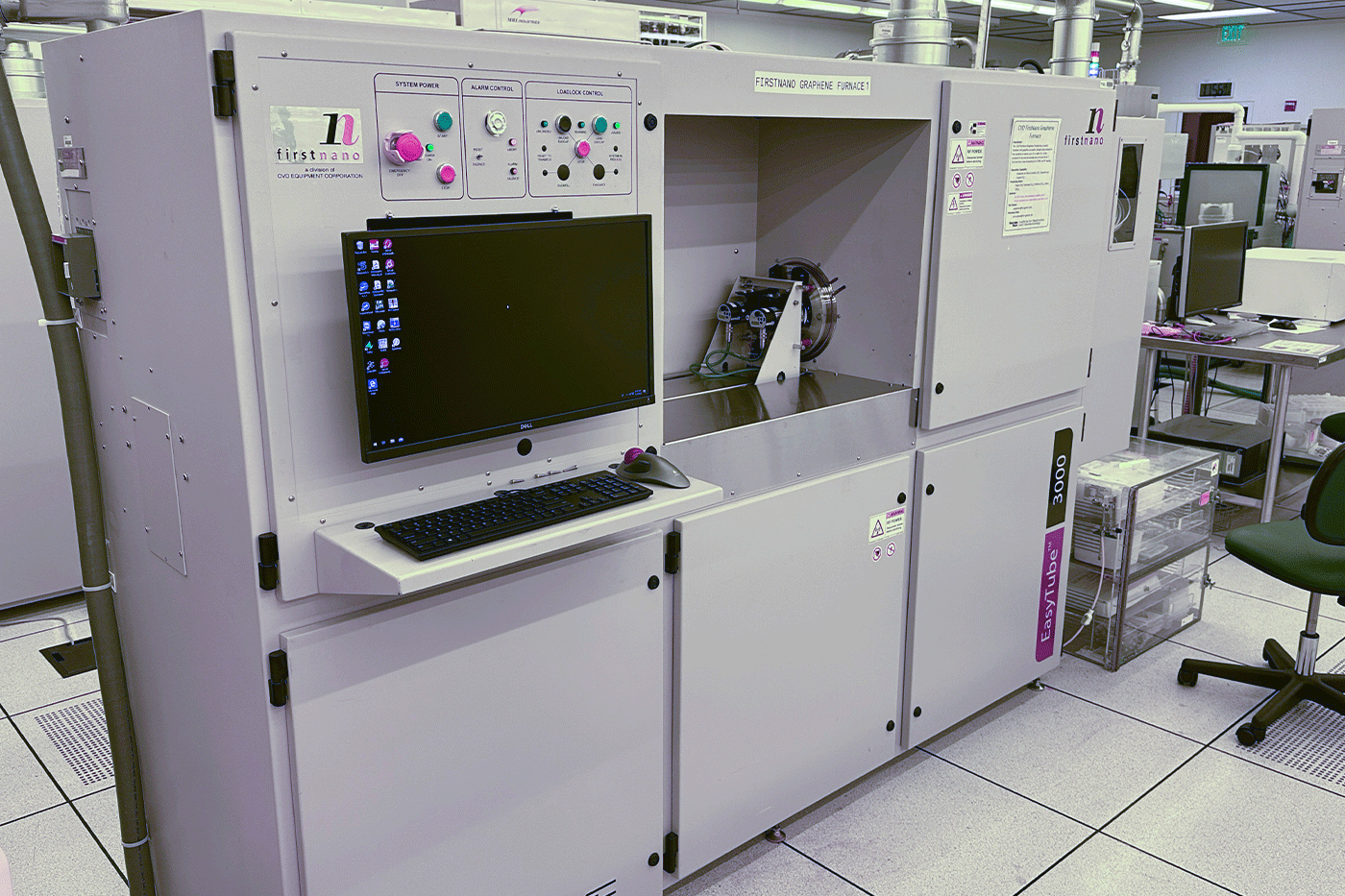

CVD FirstNano Graphene Furnace 1 (Marcus)

The Georgia Tech CVD FirstNano Graphene furnace is designed for graphene growth on Cu foil, graphene sublimation from SiC samples (epitaxial graphene), and H₂ etch cleaning of samples. It features a quartz chamber with a graphite susceptor, accommodating 3-inch wafers and small pieces, with a maximum temperature of 2200°C. The system is fully programmable and equipped with a turbo pump to achieve a low pre-processing base pressure of 9.0e-7 Torr. It supports various process gases, including Ar, H₂, SiH₄, and CH₄, and utilizes 10kW RF induction heating for precise temperature control.

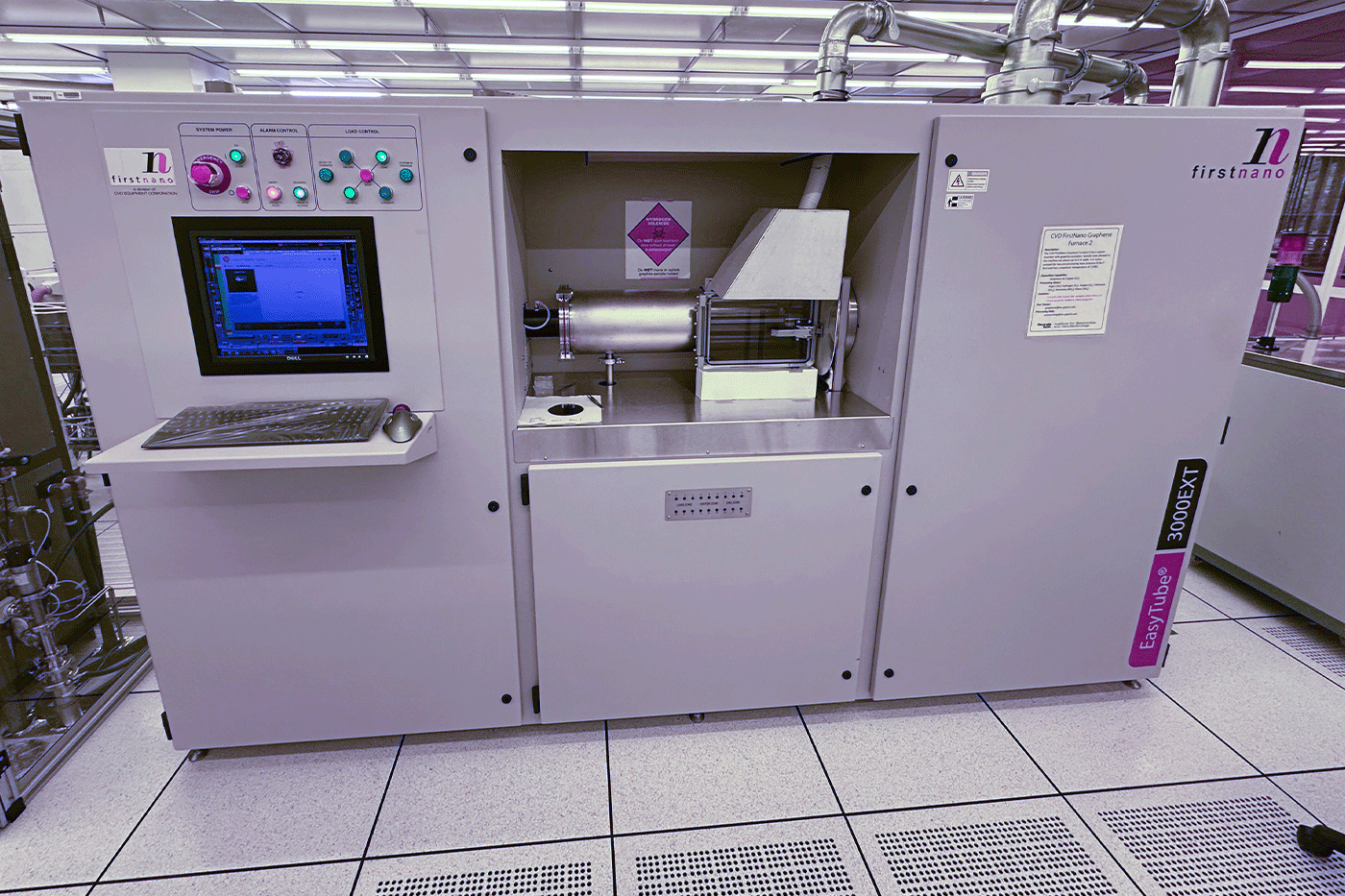

CVD FirstNano Graphene Furnace 2

The Georgia Tech CVD FirstNano Graphene 2 system is configured for graphene growth on Cu foil samples, utilizing infrared lamps for top and bottom heating. It supports 4-inch wafers and small pieces, with a maximum temperature of 1150°C. A turbo pump and load-lock enable a low base pressure of 1.0e-7 Torr, minimizing background O₂ contamination. The system is compatible with SiH₄, H₂, Ar, and NH₃ gases, ensuring precise control over the graphene growth process.

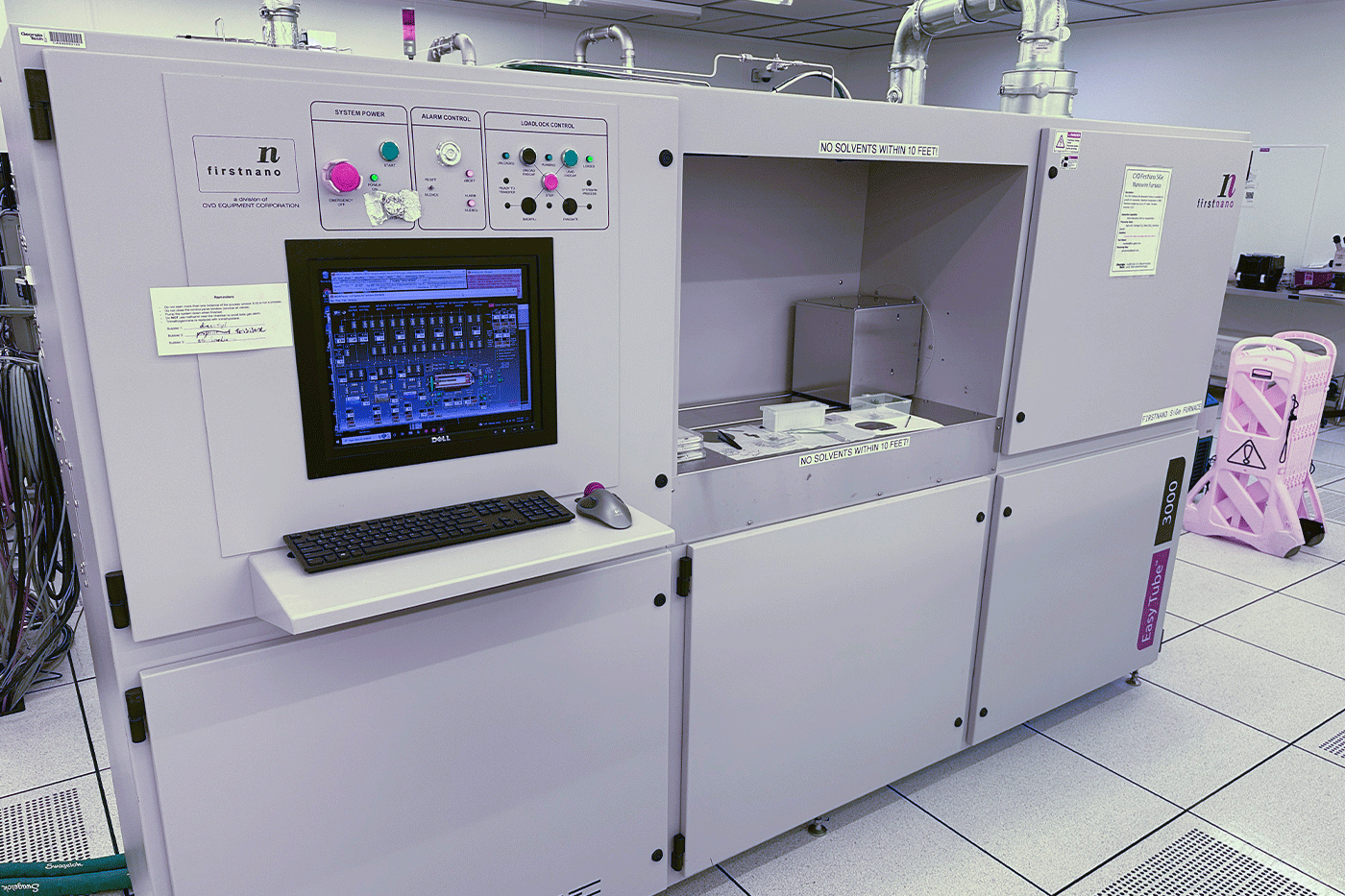

CVD FirstNano SiGe Nanowire Furnace

The Georgia Tech SiGe Nanowire furnace is designed for the deposition of Si nanowires using metal nanoparticles such as Au, typically on Si substrates. It features infrared lamp heating from the top and bottom, with a temperature range of 350°C to 900°C. The system operates at a base pressure of 1.0e-3 Torr and supports process gases including SiH₄, H₂, Ar, Ge, and 0.1% PH₃, enabling precise nanowire growth and doping control.

SSI RTP (Solaris 75)

The Georgia Tech SSI RTP system is a rapid thermal processing system designed for up to 4-inch wafers, offering precise temperature control and fast ramp rates. It supports a maximum temperature of 900°C, with higher temperatures (901°C–1100°C) available upon request. The system features mass flow controllers (MFCs) with a 10 SLM (10,000 sccm) range and a ramp rate of up to 80°C/s. Process gases include N₂, air, and O₂, ensuring flexibility for various thermal processing applications.

MRL Furnace 2

The Georgia Tech MRL Furnace 2 is used for dry oxidation at temperatures between 700 -1150°C. Batches of up to 50 wafers (4 to 6”) can be processed with excellent uniformity (less than 1%).

MRL Furnace 3

The Georgia Tech MRL Furnace 3 is a general low pressure chemical vapor deposition (LPCVD) tool used for silicon nitride deposition at temperature between 700-850°C with batches of up to 50 wafers (4 to 6”). Incoming wafers can be any type of silicon, silicon carbide, or other substrate with or without metal coatings.

CtrLayer SEF Sulfurization Furnace

The Georgia Tech sulfurization furnace is used to deposit sulfur at high temperatures. The tool is setup to inject sulfur into the chamber then allow the sulfur to soak, covering all substrates. There is a turbo pump installed on the system to allow for low base and process pressure and good process control. The maximum temperature is 1050 C with a max ramp rate of 120 C/min. Gases available are argon, hydrogen, and methane.

CVD FirstNano Graphene Furnace (Pettit)

The CVD FirstNano Furnace is capable to grow and anneal materials from small pieces up to 4 inches substrates. These are the gases that hooked up to the tool: Ar, 4%H2/N2 (4% Forming gas), and there are 2 spare MFCs that can be configured for additional 2 more gases. The furnace can be heated up to 900C.

Lindberg Furnace (Pettit)

The Georgia Tech Lindberg Furnace Tubes is designed for curing polymers, sintering, and growing oxides and nitrides on silicon wafers. It operates at a maximum temperature of 1100°C and supports process gases including nitrogen and forming gas (10% H₂ in nitrogen), providing a controlled environment for high-temperature material processing.

Lindberg Furnace 1 (CMOS Sintering Tube)

Lindberg Furnace 2 (Polymer Curing Tube)

Tystar Nitride Furnace 1

The Georgia Tech Tystar Nitride Furnace 1 is used for N-type doping and polysilicon doping (N-type) using solid PhosPlus sources. It supports common process recipes, including NDOPCOMM.001 at 1050°C and NANNEAL.001, ensuring precise doping and annealing for semiconductor applications.

Tystar Nitride Furnace 2

The Georgia Tech Tystar Nitride Furnace 2 is designed for P-type doping and polysilicon doping (P-type) using solid BoronPlus sources. It supports common process recipes, including PDOPCOMM.002 at 1050°C and PANNEAL.002, ensuring precise doping and annealing for semiconductor applications.

Tystar Nitride Wet Dry Oxidation Furnace 3

The Georgia Tech Tystar Nitride Furnace 3 is used for pad oxide, well, and field (LOCOS) oxide growth through wet oxidation processes. It operates at a maximum temperature of 1100°C, providing precise thermal oxidation for semiconductor fabrication.

Tystar Nitride Furnace 4

The Georgia Tech Tystar Nitride Furnace 4 is used for LPCVD silicon nitride deposition, including stoichiometric and low-stress silicon nitride. It supports common process recipes such as NITRCOMM.004 and LSNITRID.004, with a deposition rate of 3.46 nm/min and a refractive index of 2.28 (measured on Nov 3, 2014). The system operates at a maximum process temperature of 850°C, ensuring precise and controlled thin-film deposition.

Tystar Poly Furnace 2

The Georgia Tech Tystar Poly Furnace 2 is used for Kooi, P-well drive, and dry, and wet oxidation.

Tystar Poly Furnace 3

The Georgia Tech Tystar Poly Furnace 3 is designed for low-pressure polysilicon deposition, supporting both undoped and N-doped films. Operating at 250 mT and a deposition temperature of 588°C, it utilizes silane (SiH₄) and phosphine (PH₃) as process gases. Common recipes include POLYCOM.007, DPOLY.007, and STBY.007. The system has a maximum process temperature of 750°C, ensuring precise control over polysilicon film growth for semiconductor applications.

Tystar Poly Furnace 4

The Georgia Tech Tystar Poly Furnace 4 is used for polysilicon (undoped and P-doped) deposition at a low pressure (250 mT) and low temperature (588C) with silane (SiH4) and diborane (B2H6). Common process recipes: POLYCOM.008 BDPOLY.008 STBY.008 Max process temperature is 750C.