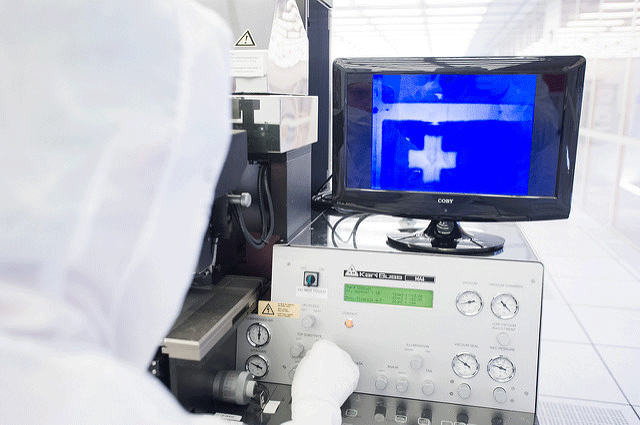

Etching

IMS cleanroom offers advanced etching capabilities, including DRIE/Bosch, ICP, RIE, and XeF₂. With tools like KLA SPTS Rapier, STS Pegasus, Plasma-Therm Versaline, and Xactix XeF₂, we enable high-aspect ratio silicon etching, dielectric patterning, and isotropic release for MEMS, photonics, and packaging.

Atomic Layer Deposition

IMS cleanroom features advanced ALD systems—Cambridge Fiji, Veeco Fiji G2, Kurt J. Lesker ALD150LX, and Oxford FlexAL—offering thermal and plasma-enhanced deposition. These tools deliver precise, conformal films of oxides, nitrides, and metals on substrates up to 200 mm at temperatures to 600°C.

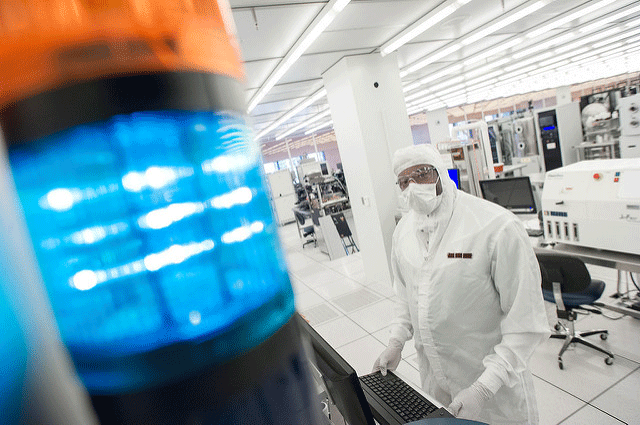

Physical Vapor Deposition

IMS PVD capabilities include e-beam and filament evaporators plus RF/DC sputtering systems for precise thin-film deposition of metals, dielectrics, nitrides, and chalcogenides. Supporting co-deposition and multi-source sputtering, IMS delivers uniform films for microelectronics, photonics, and advanced materials.

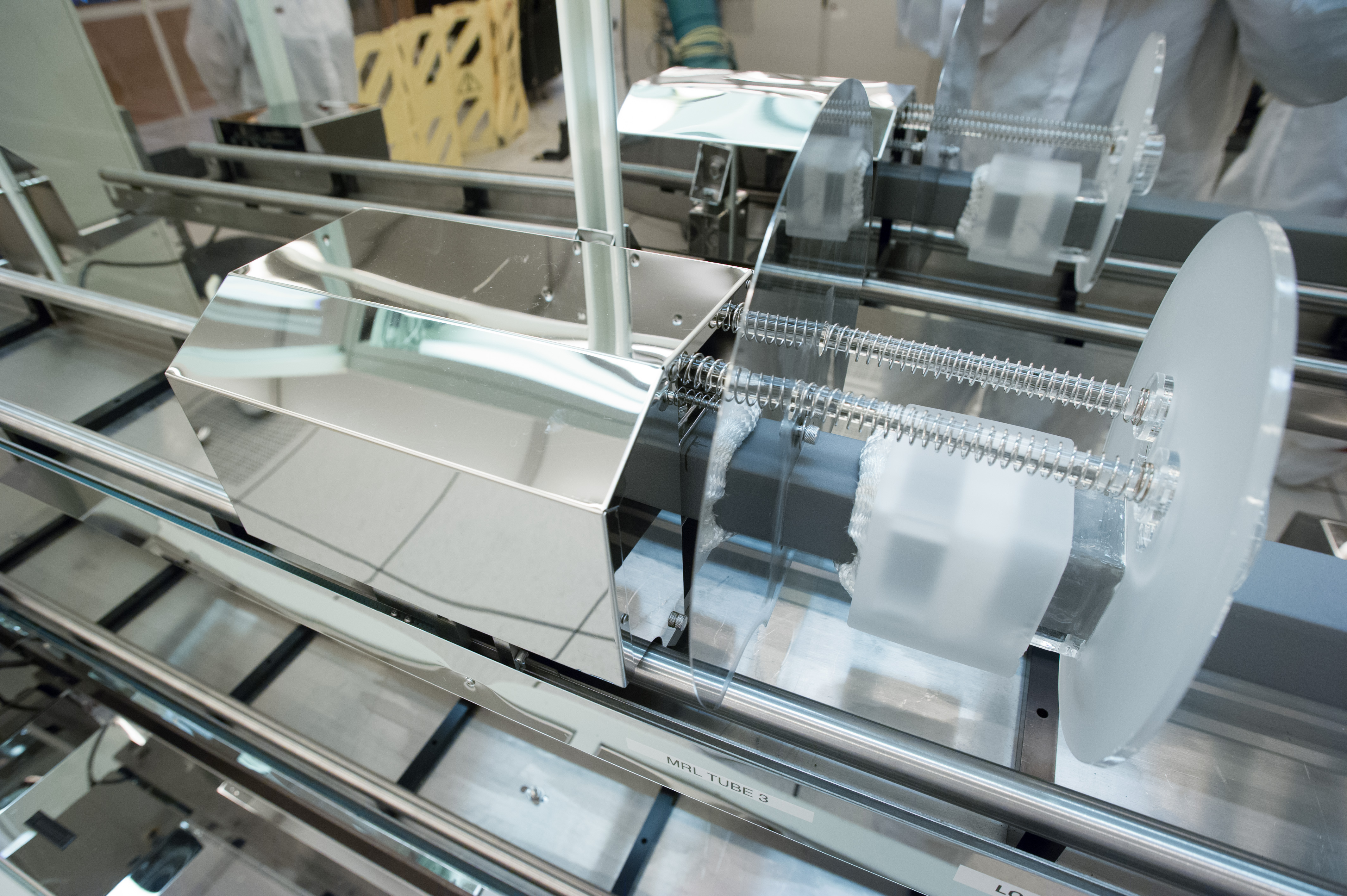

Chemical Vapor Deposition

IMS CVD tools enable thin-film deposition of oxides, nitrides, a-Si, poly-Si, graphene, and nanowires. Systems include PECVD, HDPCVD, LPCVD, APCVD, and thermal CVD. Oxford ICP-PECVD and Plasma-Therm HDPCVD deliver high-density films, while FirstNano and Black Magic support graphene, nanowire, and CNT growth.

Thermal Furnaces

IMS Furnace Suite supports oxidation, diffusion, annealing, LPCVD, sulfurization, graphene growth, and nanowire synthesis. With vacuum ovens, RTP, and high-temp CVD furnaces, users achieve precise thin-film growth, doping, and thermal treatments for semiconductor and nanomaterial research.

Wet Processing

IMS Cleanroom wet processing area offers chemical stations for wafer cleaning, etching, electroplating, and solvent handling. Capabilities include CMOS-qualified benches, solvent and acid/base hoods, multi-metal plating for Ni, Cu, Au, and PV clean benches—supporting high-purity microfabrication.