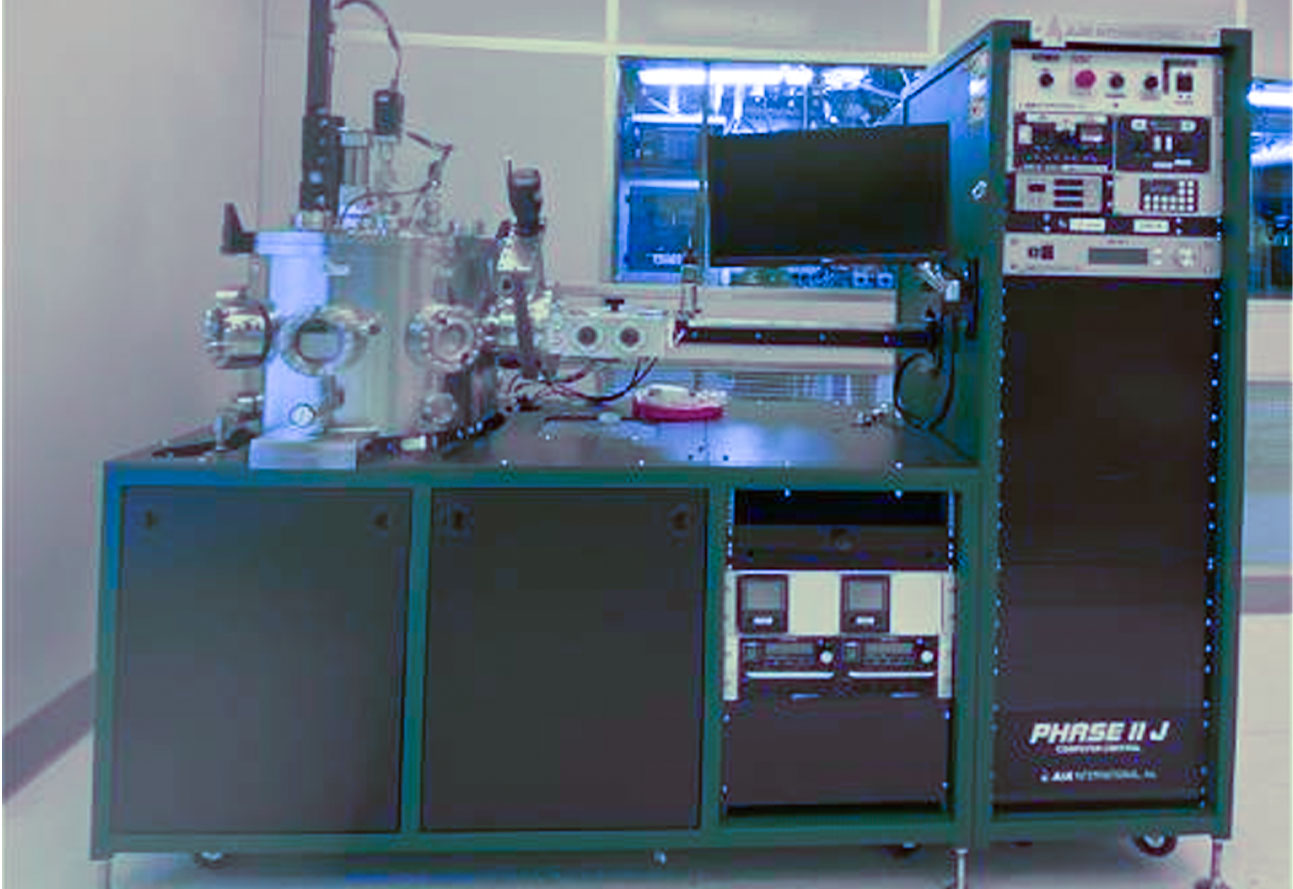

AJA Chalcogenide Sputterer

The Georgia Tech AJA Chalcogenide Multisource Sputtering System deposits thin multiphase change materials in an argon and oxygen-enriched low vacuum. The AJA Sputterer has 10 magnetron sputtering guns, 1 DC power source, 2 RF power sources, and a heater that can reach up to 400C. It can process wafers up to 4”. Co-sputtering is also available in this system. Source materials available are GST, GSST, GeTe, Sb2S3, Sb2Se3, Vo2, ZnSSiO2, ITO, GeSe3, Sb

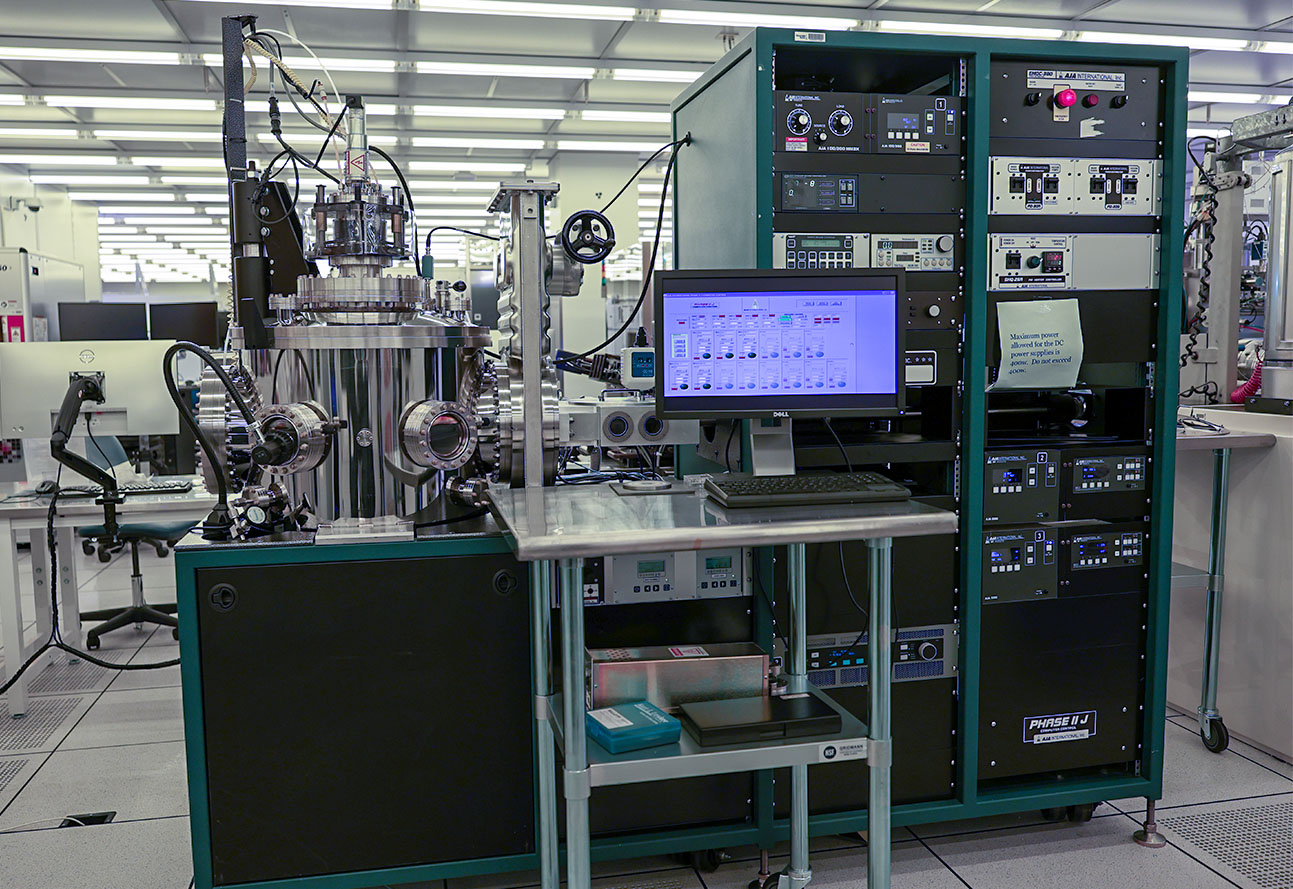

AJA Nitride Sputterer

The Georgia Tech AJA Nitride Multisource Sputtering System deposits thin metal and nitride films in an argon and nitrogen-enriched low vacuum. The AJA Sputterer has 4 magnetron sputtering guns, 2 DC power sources, 3 RF power sources, a heater that can reach up to 800C. It also has the capability of pulse dc. RF Bias is also available up to 50W. It can process wafers up to 4" -Deposition Processes: Aluminum, Aluminum Nitride, Titanium, Titanium Nitride, W, Mo, Ta, and Tantalum Nitride.

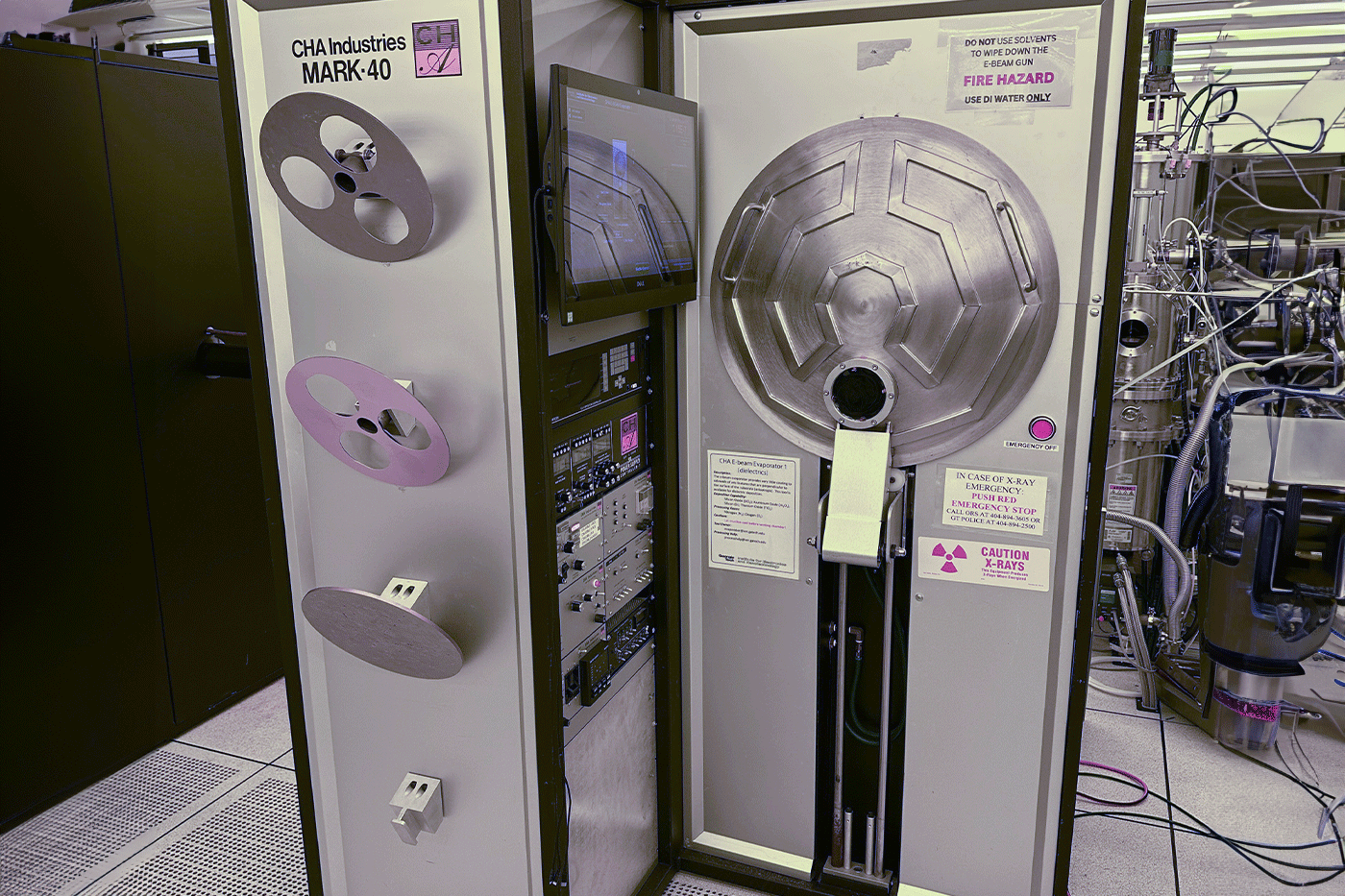

CHA E-beam Evaporator 1 (Dielectrics)

The Georgia Tech CHA 1 E-beam Evaporator is an e-beam evaporation system designed specifically for depositing dielectric materials such as SiO2, Si, TiO2, Al2O3, Ge, HfO2, and ITO. It features 20cc, 4-pocket crucibles with a direct-to-pocket O2 delivery system. The sample holder can accommodate up to three 4” wafers, and the system operates under low process pressures (5x10^-6 Torr to 5x10^-7 Torr). It includes a crystal sensor deposition monitoring system, sample rotation, and a cryopump vacuum system. The system does not have a heater but provides precise, anisotropic coating with minimal deposition on the sides of features perpendicular to the substrate.

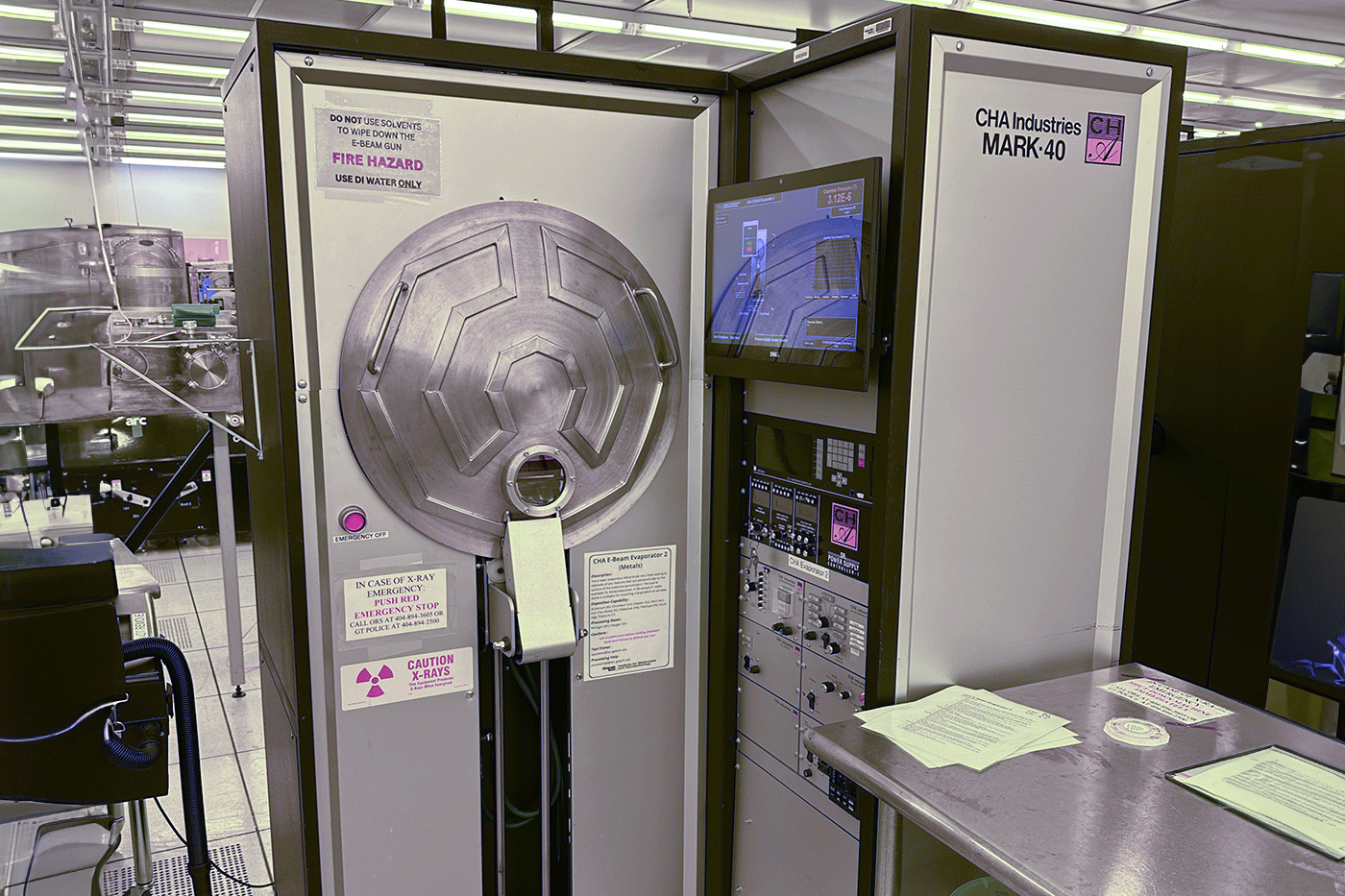

CHA E-beam Evaporator 2 (Metals)

The Georgia Tech CHA 2 E-beam Evaporator is an e-beam evaporation system designed for depositing metals such as Ti, Cr, Ni, Au, Al, Cu, and Ag. It features 25cc, 6-pocket crucibles and can hold up to three 4” wafers. The system operates under low process pressures (5x10^-6 Torr to 5x10^-7 Torr) and includes capabilities like sample rotation, a crystal sensor deposition monitoring system, and a cryopump vacuum system. The system provides minimal coating to the sides of features perpendicular to the substrate, ensuring anisotropic deposition with high precision.

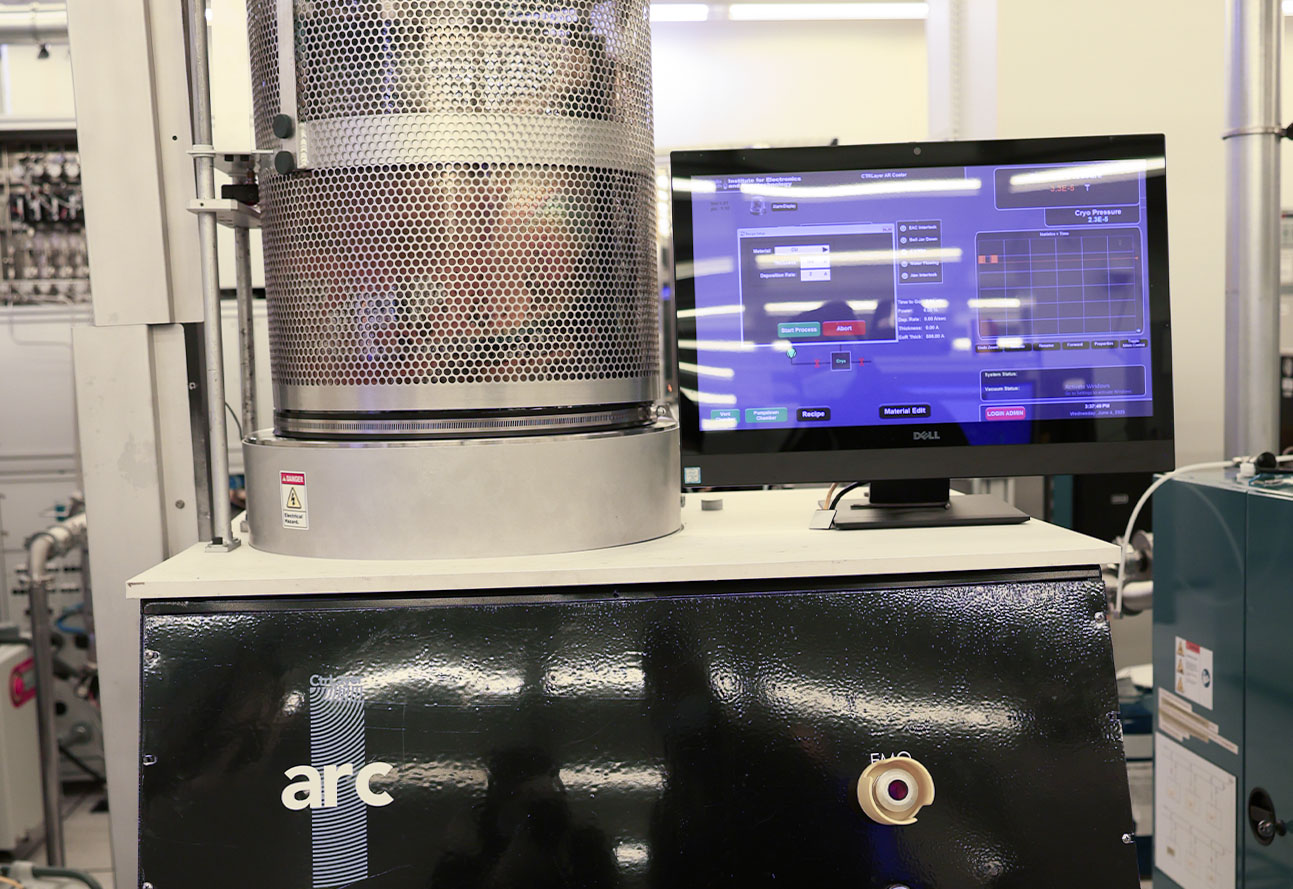

CtrLayer Anti-Reflective Coater

This tool is a thermal filament evaporator exclusively reserved for depositing unique or experimental materials. The tool features a two-step rise to soak and deposition that is automatically tuned and terminated using a crystal monitor. It is particularly useful for sensitive samples that need to avoid X-ray radiation from E-beam evaporation. The system includes an integrated touchscreen control, with the ability to handle a single substrate up to 4” and three nodes for different material sources. The system operates at pressures (5x10^-5 Torr to 5x10^-6 Torr) and includes a crystal monitor deposition controller for precise control over the deposition process. The substrate fixture can rotate up to 20 rpm for uniform coating.

CVC DC Sputterer

The CVC DC sputterer is a versatile system designed to coat samples with various metals, including Ti, Cu, Al, Cr, W, Mo, Ta, and Ag. It is equipped with two 3" and one 6" sputtering guns, as well as a six 6" sample holder rotostrate to enhance uniformity. The system supports substrate sizes of up to 6" wafers and operates at a base pressure of 5e-6 Torr with a process pressure of 5mTorr, using argon (Ar) gas. The updated touchscreen control system allows for intuitive operation and the system can run batch recipes, offering a sputtering gun shutter system and DC sputtering capabilities for reliable performance in various deposition processes Sputterer.

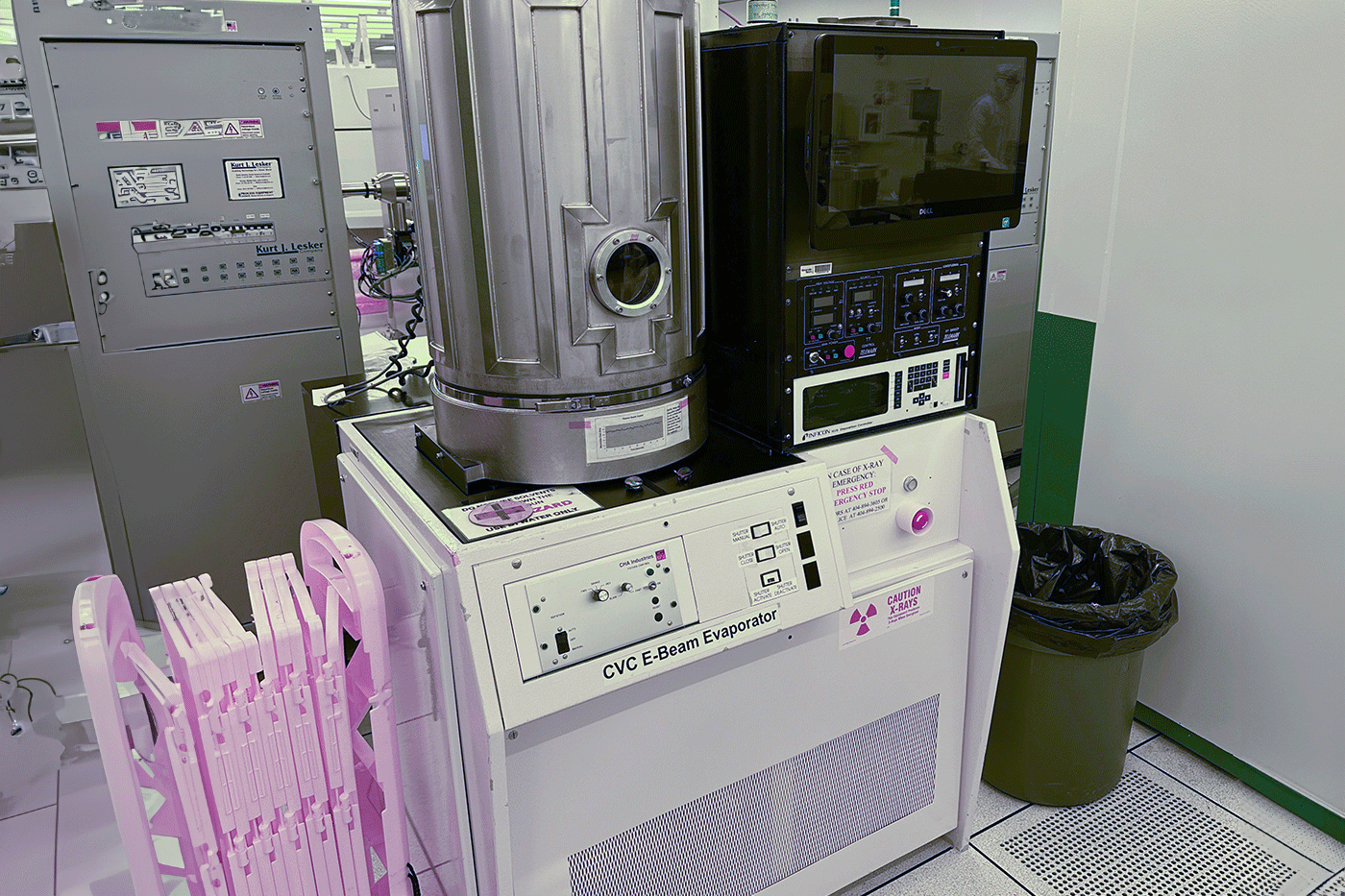

CVC E-Beam Evaporator 1

The Georgia Tech E-beam evaporator is used to coat samples with various metals such as Ti, Cr, Ni, Au, Al, Cu, and Ag. Unlike sputtered films, e-beam evaporators only coat the surface facing away from the substrate. Typical deposition rates range from less than 1 A/sec to 3 A/sec. The system includes one sample holder for up to a 6" wafer and a six 15cc pocket crucible selector. It operates at a process pressure between 5x10^-6 Torr and 5x10^-7 Torr. Key features include a crystal sensor-monitored deposition controller and automatic shutter control, ensuring precise and efficient metal deposition.

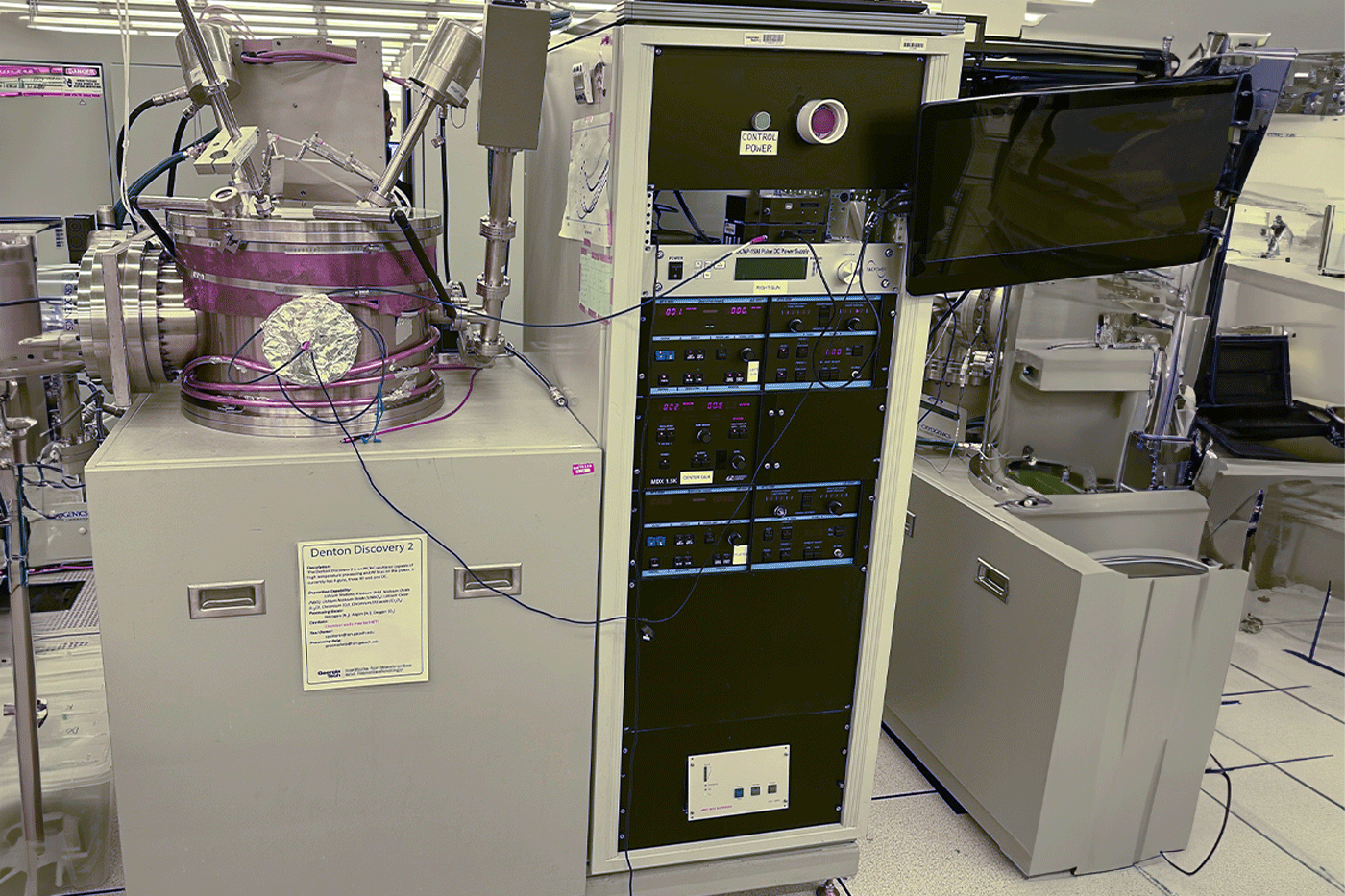

Denton Discovery - RF/DC Sputterer

The Georgia Tech Denton Discovery RF/DC Sputterer is a versatile thin film deposition system capable of sputtering up to four materials sequentially without breaking vacuum. It features four 3” sputtering guns (with one dual DC/RF gun), supports materials like Cu, Ti, Al, Cr, ITO, SiO2, Si, and Al2O3, and uses gases such as Ar, N2, and O2. The system handles substrates up to 6” wafers, operates at a pressure of 5 mTorr, and can heat samples up to 400°C. Additional features include RF bias up to 100W, sample rotation, multi-gun sputtering, load-lock system, and automatic sample loading.

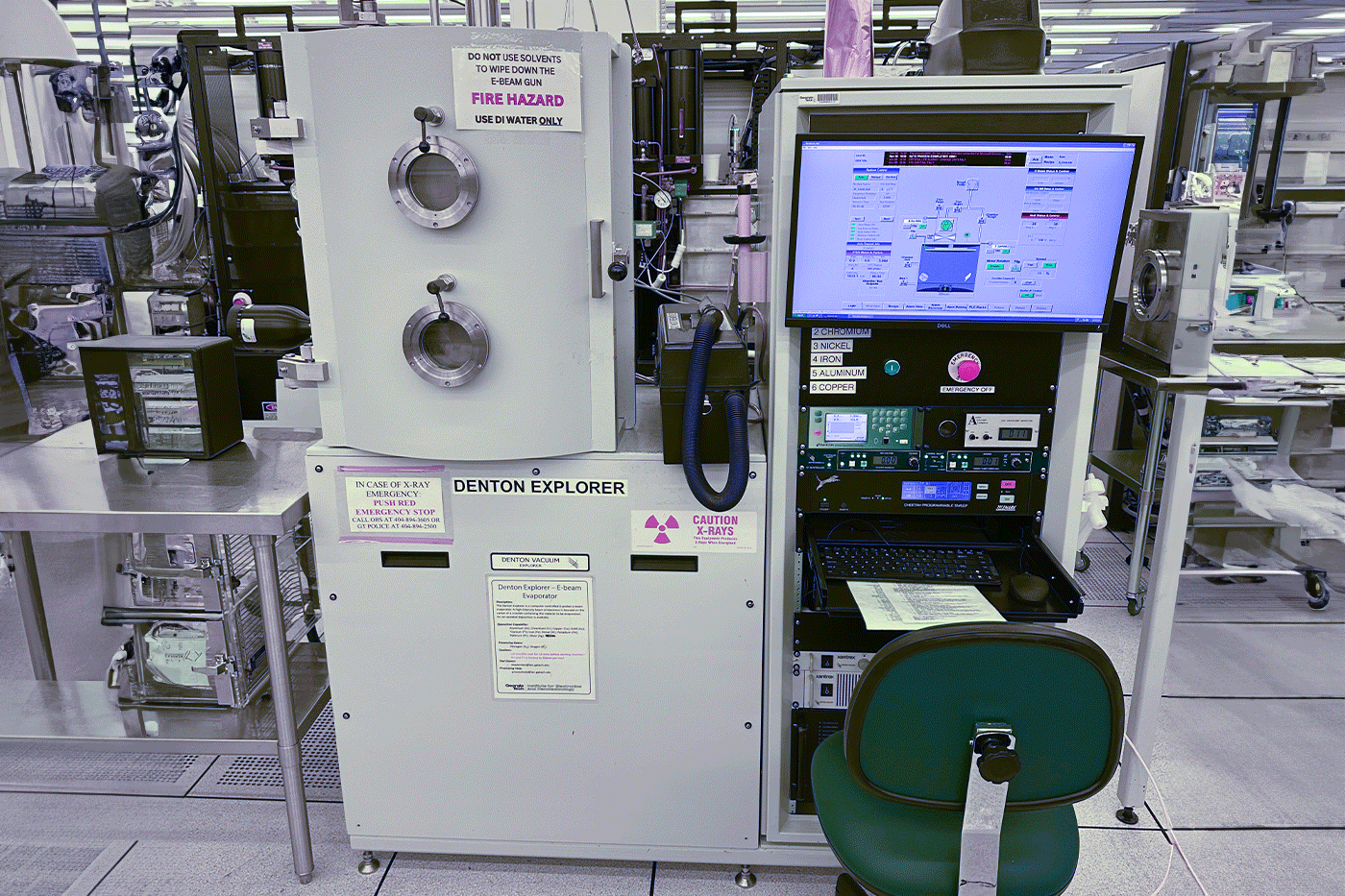

Denton Explorer

The Georgia Tech Denton Explorer is a six-pocket E-beam evaporator system used for coating samples with metals and dielectrics like Ti, Cr, Ni, Al, Cu, Au, Pt, Al2O3, SiO2, Ag, and Mo. It features three 4-inch wafer holders, a six-pocket 7cc crucible selector, and operates at ultra-low vacuum pressures (5x10^-6 Torr to 5x10^-7 Torr). The system uses Argon gas and can heat samples up to 200°C. It also supports ion-assisted deposition, crystal monitor deposition control, and includes a sample flipping feature to double the number of samples coated. The system is ideal for high-precision thin film depositions on substrates up to 4 inches in size.

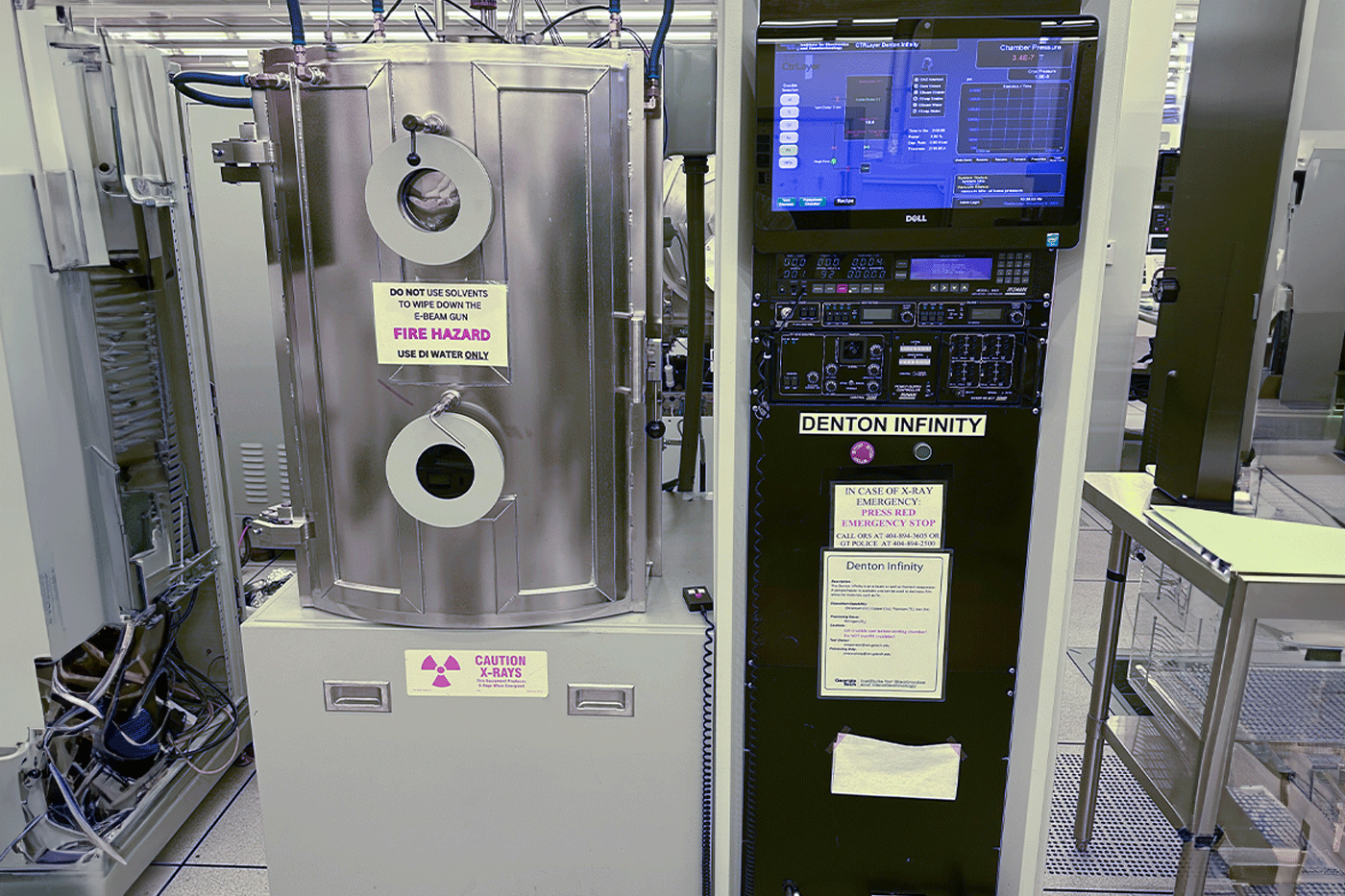

Denton Infinity

The Georgia Tech Denton Infinity is a dual-system E-beam and filament evaporator used for coating samples with metals like Ti, Cu, Al, Ni, NiFe, and Pd. It features six 25cc crucibles for material evaporation, along with a single filament evaporation node. The system supports substrates up to 6” wafers and operates at ultra-low vacuum pressures (5x10^-6 Torr to 5x10^-7 Torr). The heater can heat the samples up to 200°C, and it provides the versatility of both e-beam and filament evaporation for different deposition needs.

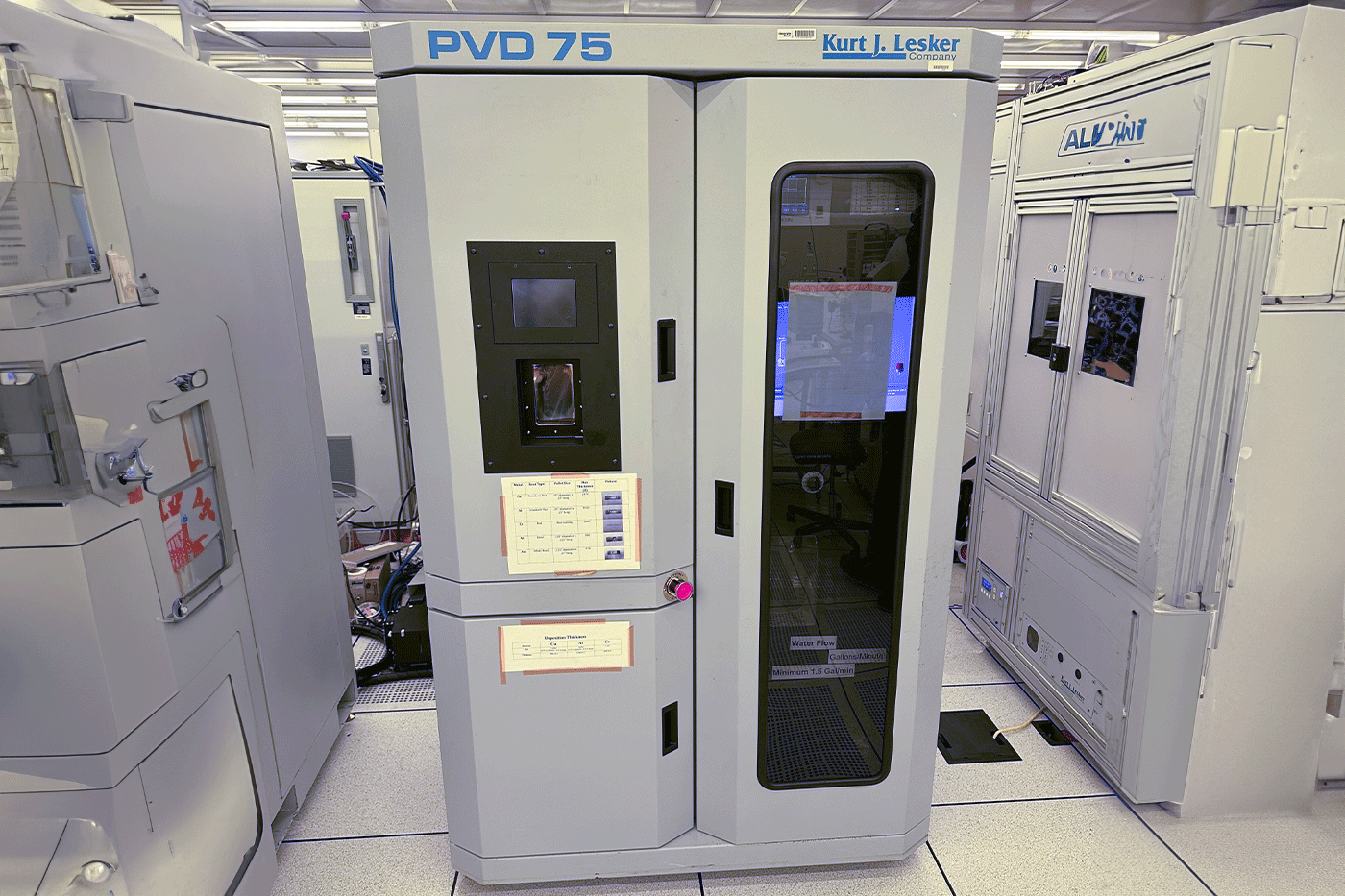

PVD75 Filament Evaporator

The Georgia Tech Filament Evaporator is a filament evaporation system designed for coating samples with metals like Al, Cu, Cr, and Au. It is particularly useful for sensitive samples that need to avoid X-ray radiation from E-beam evaporation. The system includes an integrated touchscreen control, with the ability to handle a single substrate up to 12” in diameter or multiple substrates up to 4” in diameter. It features a 12” diameter sample holder and three nodes for different material sources. The system operates at ultra-low vacuum pressures (5x10^-6 Torr to 5x10^-7 Torr) and includes a crystal monitor deposition controller for precise control over the deposition process. The substrate fixture can rotate up to 20 rpm for uniform coating.

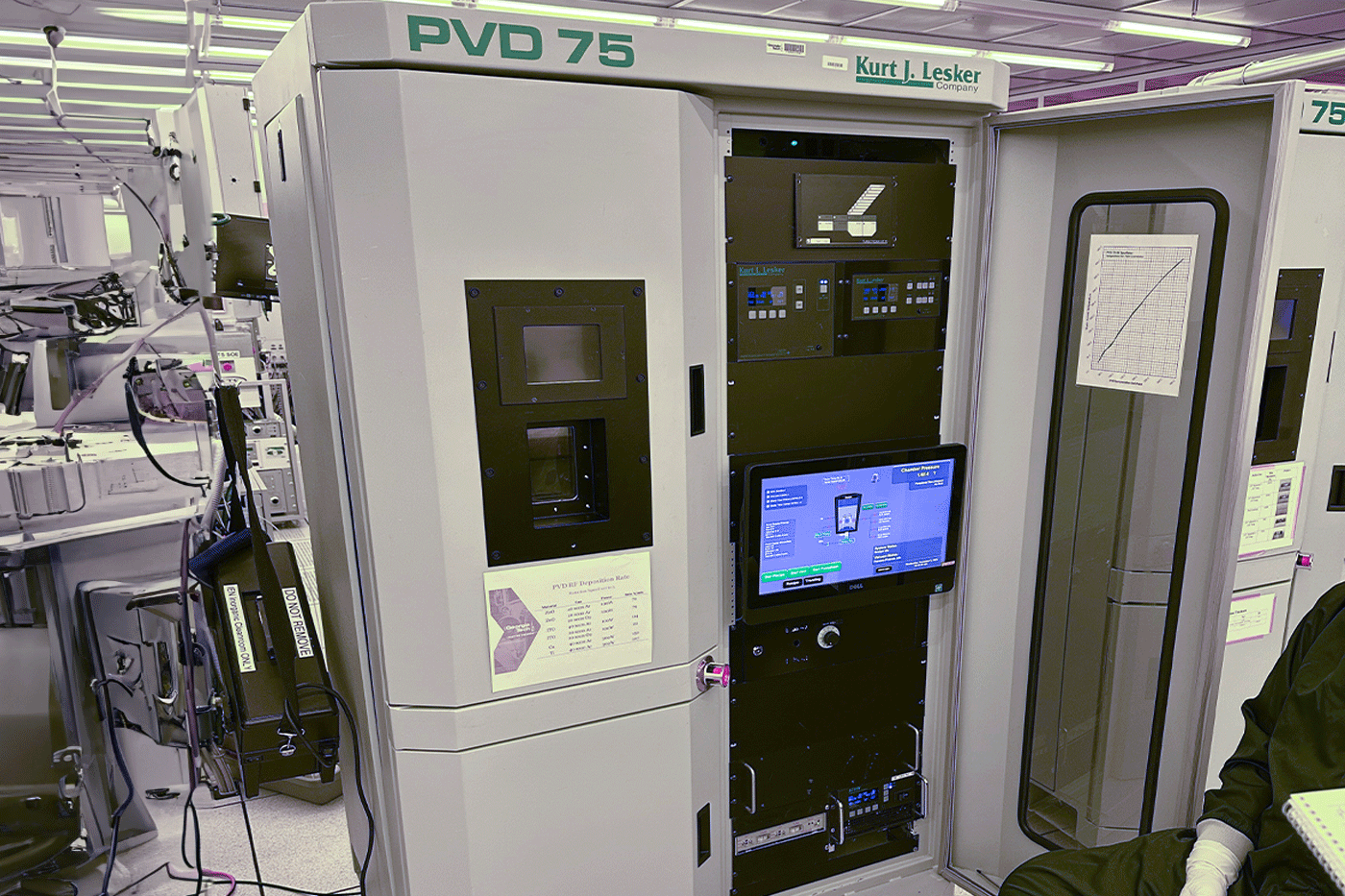

PVD75 RF Sputterer 1

The PVD75 RF Sputterer is an RF sputtering system designed for depositing dielectrics by accelerating ions or an argon-oxygen mixture onto a sputter target. It allows for co-deposition, where two or more dissimilar materials can be sputtered simultaneously, providing complete control over film stoichiometry. The system features two 3” sputtering guns, a 12” diameter sample holder, and integrated touchscreen control. It supports single substrates up to 12” in diameter or multiple substrates up to 4” in diameter, with a substrate fixture rotation of up to 20 rpm for uniform coating. Operating at a process pressure of 5 mTorr, it uses gases such as Ar, O2, and N2, and has a maximum RF power of 125W for dielectric materials and 500W for metals. The system also includes two RF power supplies and tuning networks for co-deposition. Both sputtering guns have shutters for a controlled deposition.

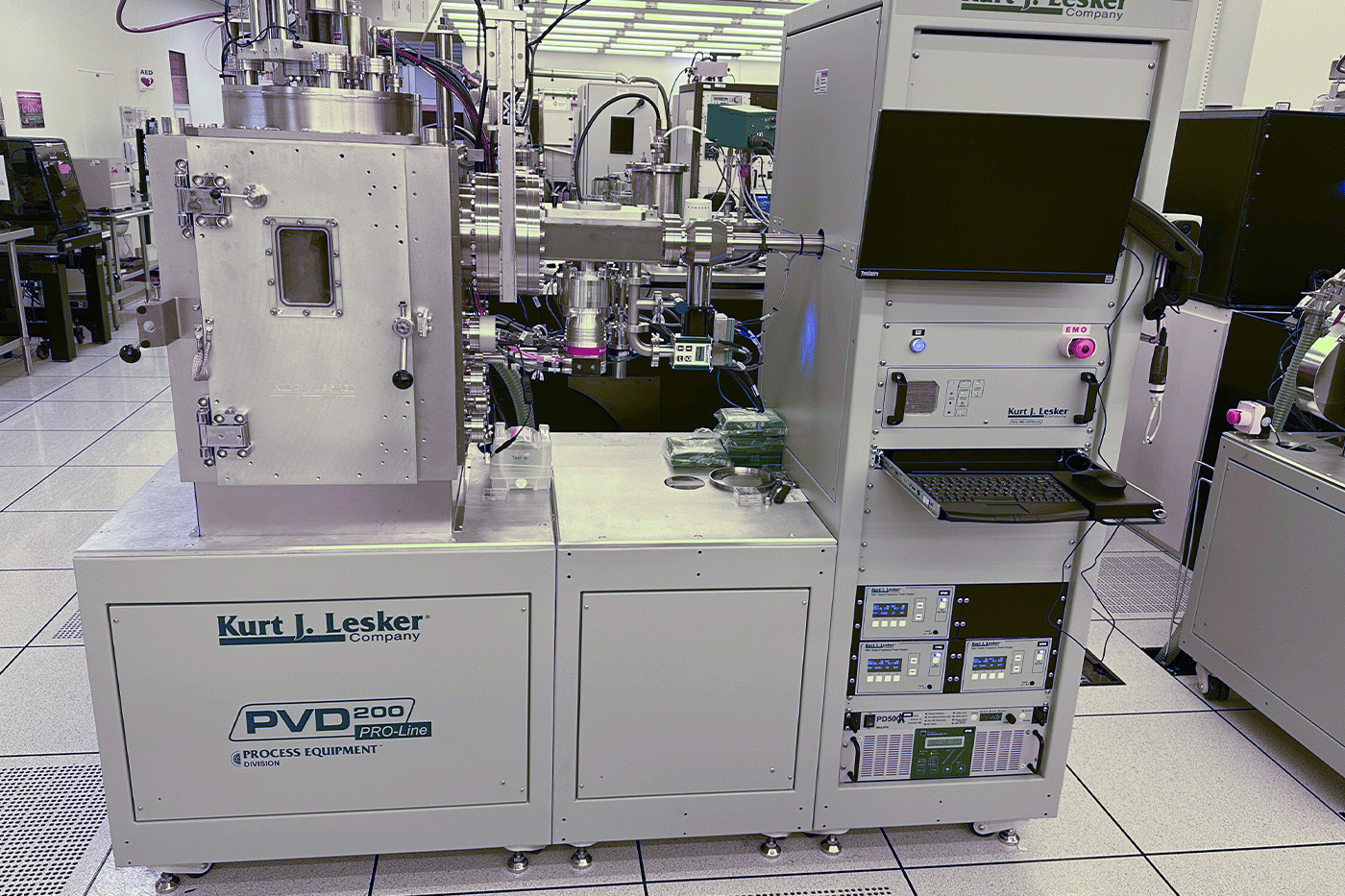

PVD200 RF/DC Sputterer 1 Oxide

The PVD200 RF/DC Sputterer is an RF/DC sputtering system designed for depositing metals and dielectrics by accelerating ions or an argon-oxygen mixture onto a sputter target. It allows for co-deposition, where two or more dissimilar materials can be sputtered simultaneously, providing complete control over film stoichiometry. The system features four 3” sputtering guns, a 6” diameter sample holder, and integrated touchscreen control. It supports single substrates up to 6” in diameter with a substrate fixture rotation of up to 20 rpm for uniform coating. Operating at a process pressure of 3 mTorr, it uses both RF and DC power of 125W for dielectric materials and 200W for metals. The system also includes two RF power supplies and tuning networks for co-deposition, pulse dc and regular dc power supplies. There are shutters for all 4 sputtering guns as well as a sample holder shutter. The heater in the system can reach up to 400C. It has an automatic sample loading system with a loadlock supported by turbo pump. Materials available are Ti, Ni, Pt, IWO, W and ITO.

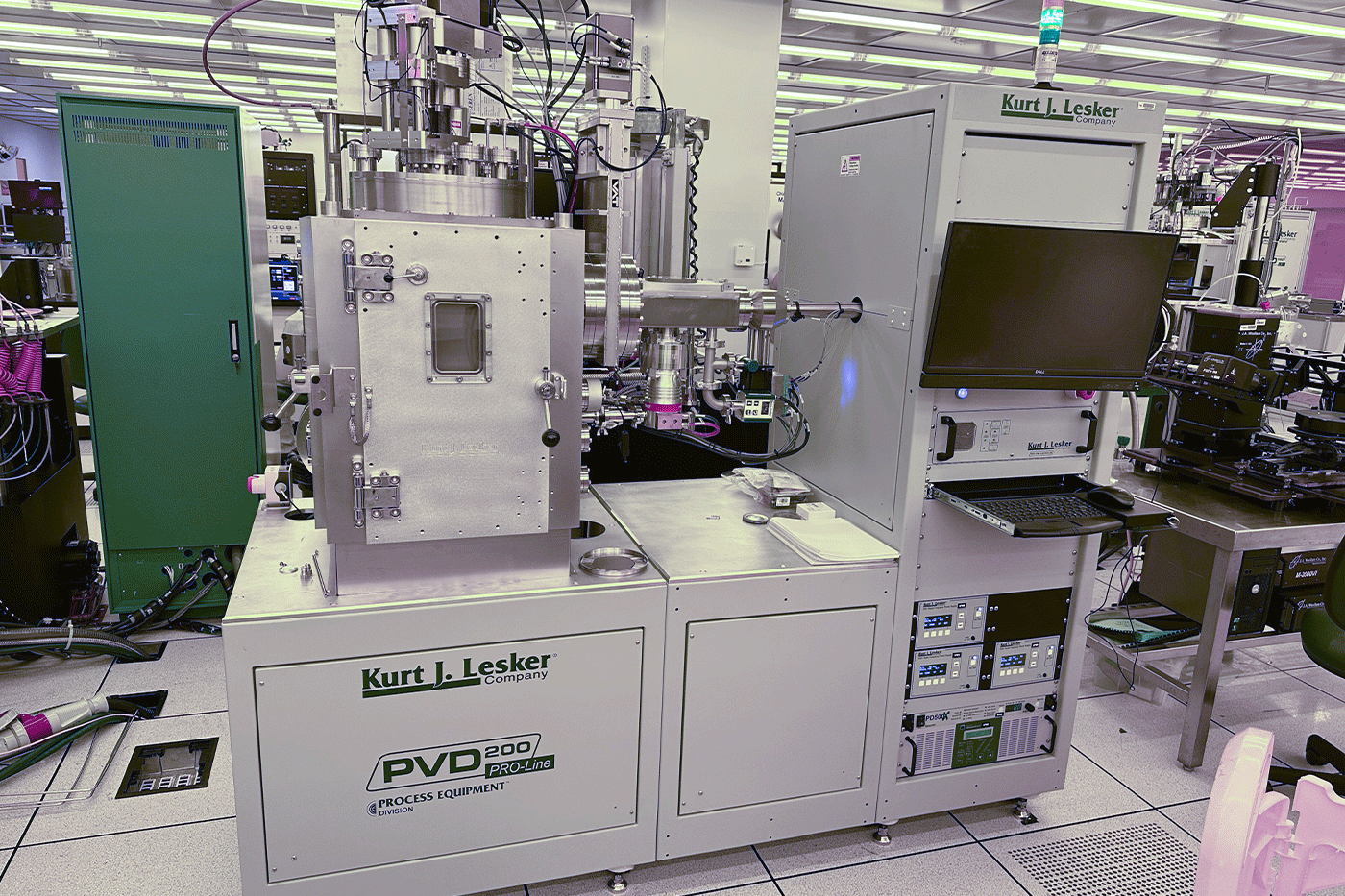

PVD200 RF/DC Nitride Sputterer 2 Nitride

The PVD200 RF/DC Sputterer is an RF/DC sputtering system designed for depositing metals and dielectrics by accelerating ions or an argon-nitrogen mixture onto a sputter target. It allows for co-deposition, where two or more dissimilar materials can be sputtered simultaneously, providing complete control over film stoichiometry. The system features four 3” sputtering guns, a 6” diameter sample holder, and integrated touchscreen control. It supports single substrates up to 6” in diameter with a substrate fixture rotation of up to 20 rpm for uniform coating. Operating at a process pressure of 3 mTorr, it uses both RF and DC power of 125W for dielectric materials and 200W for metals. The system also includes two RF power supplies and tuning networks for co-deposition, pulse dc and regular dc power supplies. There are shutters for all 4 sputtering guns as well as a sample holder shutter. The heater in the system can reach up to 400C. It has an automatic sample loading system with a loadlock supported by turbo pump. Materials available are Ti, Sc, W, and Al.

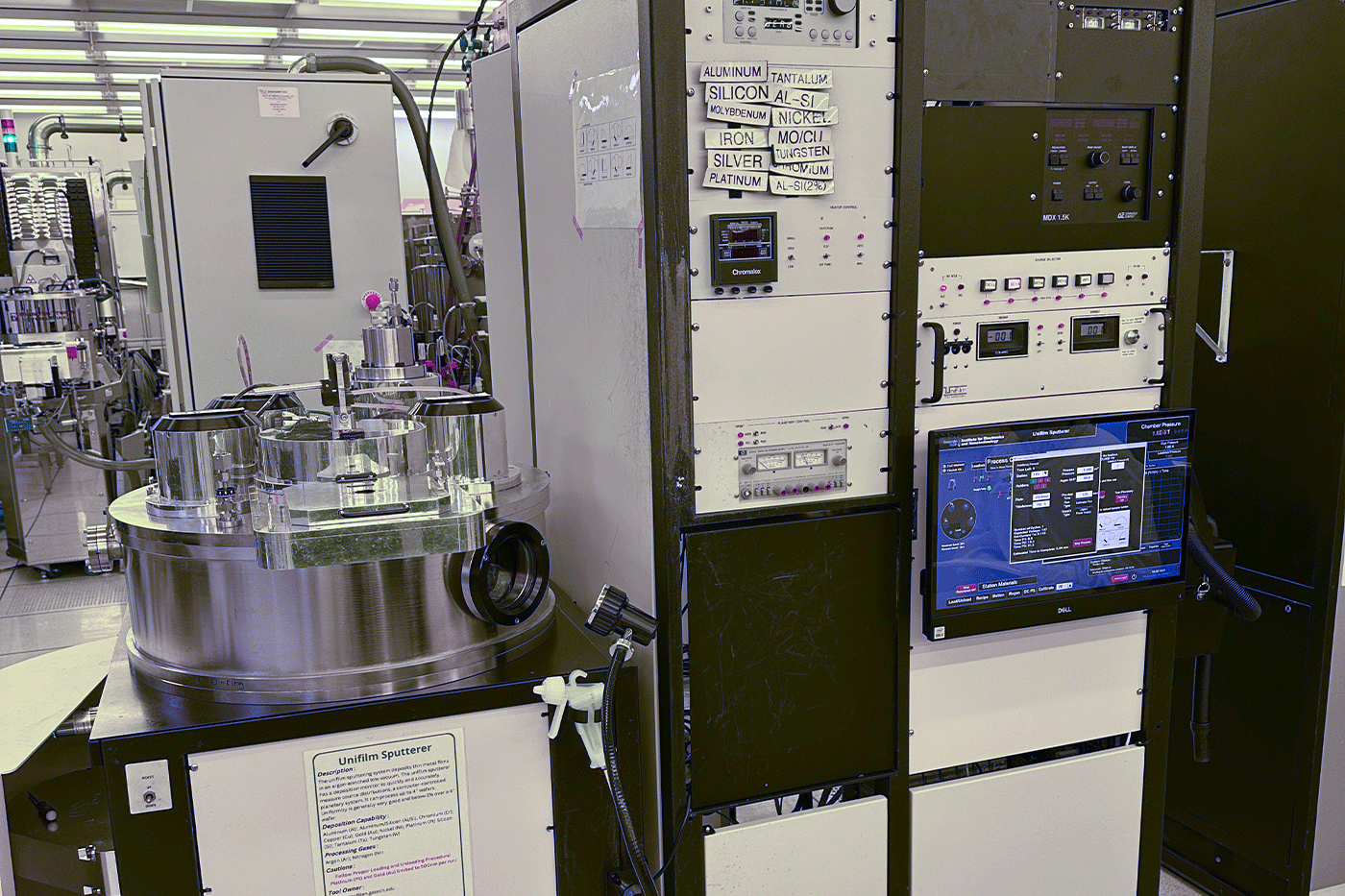

Unifilm Sputterer 1

The PVD200 DC Sputterer is a DC sputtering system designed for depositing metals and by accelerating ions onto a sputter target. The system features four 3” sputtering guns, Three 6” diameter sample holders, and integrated touchscreen control. Each sample holder supports a single substrate up to 4” in diameter with a unique substrate fixture rotation for uniform coating. Operating at a process pressure of 5 mTorr, the system can deposit up to four different materials using a DC power supply. The chamber can reach base pressures from 5x10-6T to 9x10-8T. It utilizes a crypump to reach a high vacuum. Materials currently available in the system include Ti, Cr, Al, Cr, Au, Pt, Ni, Pd, Mo, Ta, W, and Ag.