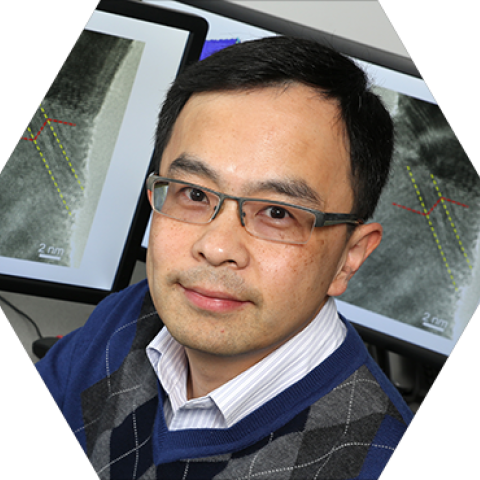

Mark Losego

Mark D. Losego is a professor in the School of Materials Science and Engineering at Georgia Tech. The Losego research lab focuses on materials processing to develop novel organic-inorganic hybrid materials and interfaces for microelectronics, sustainable energy devices, national security technologies, and advanced textiles. The Losego Lab combines a unique set of solution and vapor phase processing methods to convert organic polymers into organic-inorganic hybrid materials, including developing the science to scale these processes for manufacturing. Prof. Losego’s work is primarily experimental, and researchers in his lab gain expertise in the vapor phase processing of materials (atomic layer deposition, physical vapor deposition, vapor phase infiltration, etc.), the design and construction of vacuum equipment, interfacial and surface science, and materials and surface characterization. Depending on the project, Losego Lab researchers explore a variety of properties ranging from electrical to electrochemical to optical to thermal to sorptive to catalytic and more.

Catalysis; Cellulose Nanomaterials; Coatings; Coatings and Barriers; Corrosion & Materials Engineering; Corrosion and Reliability; Energy; Films and Coatings; Microporous Materials; Nanocellulose Applications; Nanomaterials; New Materials; Polymers; Vapor Phase Processing